Summary Report | February 2021

The Intergovernmental Panel on Climate Change (IPCC): “Limiting warming to 1.5 degrees C will require removing carbon from the atmosphere in addition to reducing emissions.”

Authors

The research team from the Carbon Leadership Forum at the University of Washington College of Built Environments:

- Julie Kriegh, PhD, AIA, Research Scientist, Carbon Leadership Forum, Department of Architecture, College of Built Environments, University of Washington.

- Chris Magwood, Director, Endeavor Center, The Sustainable Building School, Peterborough, Ontario, Canada.

- Wil Srubar III, PhD, Associate Professor, University of Colorado Boulder, Civil, Environmental and Architectural Engineering, Materials Science and Engineering Program.

Version: February, 2021

Acknowledgments

The research team would like to thank Microsoft for funding this research and the following individuals: Danielle Decatur, Microsoft, Principal Program Manager of Datacenter Sustainability; Sean James, Microsoft, Director of Datacenter Research; Ben Stanley, WSP Sustainability, Energy and Climate Change consultant and project manager and the WSP team Sebastian Danio-Beck, Ryan Dick, Sarah Buffaloe, and Lama Bitar for their work on the project including the WBLCA and technical support; Kurt Swensson, PhD, PE, KSi structural engineering consultant for his work on the data center engineering models and specifications review; Monica Huang, Research Engineer, and Brook Waldman, researcher and consultant with the Carbon Leadership Forum for their assistance in preparing this report.

A carbon-positive future in three to five years?

The Carbon Leadership Forum at the University of Washington has recently completed a four-month research project with a major US tech company to understand the potential of using low-carbon and carbon-storing materials in new construction. The project focused on carbon-intensive hotspot materials (e.g., concrete foundations and slab floors, insulated roof and wall panels, and structural framing) in light industrial buildings.

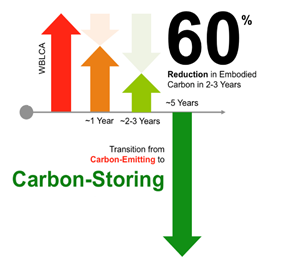

The study found that a sizable reduction (~60%) in embodied carbon is possible in two to three years by bringing readily-available low-carbon materials into wider use. Furthermore, this work predicts that fostering a carbon-storing material supply system by investing in the development and manufacturing of nascent carbon-storing materials industries will make a carbon-positive future for individual projects possible in three to five years (see Figure 1).

Figure 1. Potential carbon reductions (credit: Wil Srubar).

Executive Summary

Why is this strategy important?

The International Panel on Climate Change (IPCC) has established that reductions in carbon emissions alone are not enough to curtail climate disaster. Therefore, it is crucial that we systematically draw down and store carbon. Over the next 30 years, embodied carbon, namely emissions associated with the procurement, manufacturing, construction use, and disposal of building materials, is predicted to account for almost 50% of all new construction-related carbon emissions (Architecture2030). Addressing these emissions now is critical since embodied carbon emissions are committed at a building’s inception and remain constant throughout the life of a building.

A key strategy

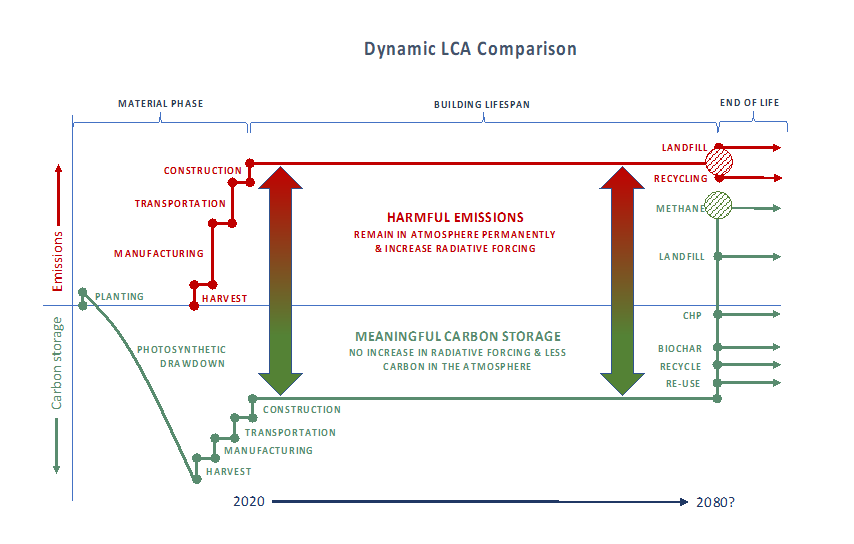

We can convert buildings from being an existential climate threat (emissions source) to a significant climate solution (emissions sink) by using biogenic materials that store carbon and reduce emissions during the production of construction materials. Emissions sinks are crucial to achieving decarbonization by 2030 because carbon has a time value; the impact of photosynthetic drawdown exerts the most impact at the beginning of the building process (see Figure 2).

Another key strategy can be found in the use of rapidly renewable biogenic carbon-storing building materials produced from biomass (e.g., annually harvested agricultural residues and purpose-grown fibers). Indeed, the use of biogenic materials renders possible not only upfront photosynthetic drawdown but also the potential for long-term carbon positivity. Both are crucial to achieving decarbonization by 2030 because achieving upfront photosynthetic drawdown in the early stages of the building process exerts the greatest impact on emissions and climate.

What are the broader impacts?

It is possible to catalyze building decarbonization by establishing a new socio-techno-economic model that promotes building with biomass. Biogenic building materials made from biomass – underutilized agricultural residues (e.g., rice hulls, wheat straw, and bamboo leaf ash, sunflower stalks, sugar bagasse) and purpose-grown fibers (e.g., bamboo, cork, hemp, algae, and seaweed) – have the potential to create new building products (Cantor & Manea, 2015; Liuzzi, S., 2017; Maraveas, C., 2020).

Building with these biogenic materials also has the promise to catalyze new manufacturing hubs, create jobs, provide training and education opportunities, and reduce the need for traditional, emissions-intensive disposal methods of waste fibers (e.g., incinerating, landfilling, composting). In addition, the carbon avoided and carbon stored in buildings represents a new asset class of carbon products for emerging carbon marketplaces. Taken together, these strategies are estimated to contribute to significant (> 1 gigatons of CO2 per year) reductions of total carbon emissions globally (Churkina, G., et al. 2020; Habert, G., et al. 2020; Frank, S., et al, 2018).

This work proposes that, by pairing communities where biogenic materials are harvested with companies (industry partners) where manufacturing and construction services occur, we can reduce upfront emissions in the building industry. We can also cut emissions associated with underutilized agricultural residues while catalyzing new carbon and building product markets and strong economies, producing multiple co-benefits.

Over the next 30 years, embodied carbon, namely emissions associated with the procurement, manufacturing, construction use, and disposal of building materials, is predicted to account for almost 50% of all new construction-related carbon emissions (Architecture 2030).

Figure 2. Photosynthetic drawdown (Credit: Chris Magwood)

UNEP and IEA, “Global Status Report 2017: Towards a Zero-Emission, Efficient, and Resilient Buildings and Construction Sector,” 2017.

OECD, “Global Material Resources Outlook to 2060: Economic Drivers and Environmental Consequences” (Paris, 2019), https://doi.org/https://doi.org/10.1787/9789264307452-en.

1 Introduction

1.1 Context

Globally, the building and construction sectors account for nearly 40% of global energy-related carbon dioxide emissions through the construction and operation of buildings (including the impacts of upstream power generation) Current building codes address operating energy but typically overlook the impacts “embodied” in building materials and construction products. In fact, when aggregated across industry sectors, more than half of all GHG emissions relate to materials management (including material extraction and manufacturing). As building operations become more efficient, managing the embodied impacts related to producing and installing building materials becomes increasingly significant.

Meaningful embodied carbon reductions can be achieved using materials on the market today. Carbon-storing materials, both bio-based (such as mass timber) and mineral-based (e.g., emerging concrete products and concrete utilizing carbon capture and storage (CCS) technology), demonstrate the feasibility of using building materials to store carbon. Indeed, if the amount of carbon stored in a building exceeds the amount emitted during materials extraction, the building can be considered a “carbon sink” (Churkina et al., 2020). Though many carbon-storing materials are available on the market today, others are still in early development and deployment stages and require testing in order to gain market acceptance and scale in use.

Our research project focused on a light industrial building. This typology provides a unique testing ground for innovations in carbon-storing materials due to the unique performance requirements, high operating energy demands, and 15-year projected lifespan of these types of buildings. Given the industry’s continuing plans to develop, build, and operate light industrial campuses, we believe our research question carries broad implications and merit:

What is required to exceed carbon neutrality targets by storing enough carbon in building materials for the building to become a net carbon sink?

By exploring both immediate and emerging strategies for embodied carbon reduction and storage, we tested our research question and developed a methodology and low-carbon and carbon-storing materials roadmap with potential for a broad impact.

Carbon-storing materials, both bio-based (such as mass timber) and mineral-based (e.g., emerging concrete products and concrete utilizing carbon capture and storage (CCS) technology), demonstrate the feasibility of using building materials to store carbon.

1.2 Project vision: Designing for carbon-storing materials systems

The Carbon Leadership Forum (CLF) was hired as a consultant in January of 2020 by a US technology company to identify opportunities for material substitutions to promote the decarbonization of their light industrial buildings in their new technology center building projects.

These technology centers, by virtue of their sheer size, rapid proliferation, and high use of resources, possess a unique ability to impact global, national, regional, and community building scales and manufacturing hubs. As such, the work of this project utilizes a “systems-of-system” (SoS) approach, based on our understanding that researchers, industry professionals, businesses, markets, and supply chains are components of numerous complex, integrated systems situated globally, regionally, and in local communities (see Section 1.5 for more SoS information). The measure of success for this carbon-storing project was our collective ability to help inform and guide decisions and actions in the design and building of these campuses, potentially inspiring thousands of individuals and companies in the industry to follow suit by reducing embodied carbon emissions in the most powerful and impactful ways.

Using an SoS approach to the design, construction, and operation, a technology center campus can serve as the nexus of a community of buildings, strategic innovation, and more. It can also weave a socio-techno-economic fabric that enables carbon reductions while catalyzing new regional manufacturing industries to join in the construction of a connected community of buildings beyond the technology center campus. Furthermore, increased use of new carbon-storing materials may encourage the development of new tools, databases and banking methodologies industry-wide.

A technology center campus can weave a socio-techno-economic fabric that enables carbon reductions while catalyzing new regional manufacturing industries to join in the construction of a connected community of buildings beyond the technology center campus.

1.3 Project values

Serving as imperatives for the project, the following values guided the project’s SoS approach:

- Lead by example. Set new and disruptive business-as-usual standards for a business impact with a global reach in embodied carbon in campus design.

- Influence materials production. Support manufacturing practices to foster industry adoption.

- Take a holistic approach. Design and build entire material supply systems, identifying mutual co-benefits in the local community, environment, and economy.

- Be future-ready. Consider the use of technologies and infrastructures responsive to the call for innovation and scalable solutions designed for an as-yet unknown technology future.

1.4 Project goals and recommendations

From this set of four underpinning values, the team created an index of low-carbon and carbon-storing materials to consider, vet, and evaluate. The materials index examined a range of products as a basis from which to evaluate opportunities and challenges for use in building design. This materials index (see Section 7) was honed over the course of the project into specific goals for recommendations in the following three time frames:

- Immediate 1-to-1 substitutions (one-year time frame). These recommendations are intended to provide embodied carbon reductions via material substitutions widely available, fulfilling the intent of the current building design without the need for a redesign.

- Near-future use (two- to three-year timeframe). These recommendations are intended to provide significant embodied carbon reductions via biogenic material substitutions and mineralized carbon products available on the market and may require component redesign without altering the basic geometry or form of the current light industrial building design.

- Carbon-positive future (three- to five-year timeframe). These recommendations include biogenic and mineralized material substitutions that are not yet widely available. Some of these materials would work with the current building design and require only component redesign, but others would require an overall redesign of the building. Included in the carbon-positive future are materials currently in small-scale production as well as those in various stages of research and development. These developmental opportunities are termed “quantum-leap” opportunities because they disrupt business-as-usual design practices. The carbon-positive future options present opportunities to progress beyond embodied carbon reductions at the material level toward the project goals as described in the system-of-systems approach outlined below.

Some of these biogenic materials would work with the current building design and require only component redesign, but others would require an overall redesign of the building.

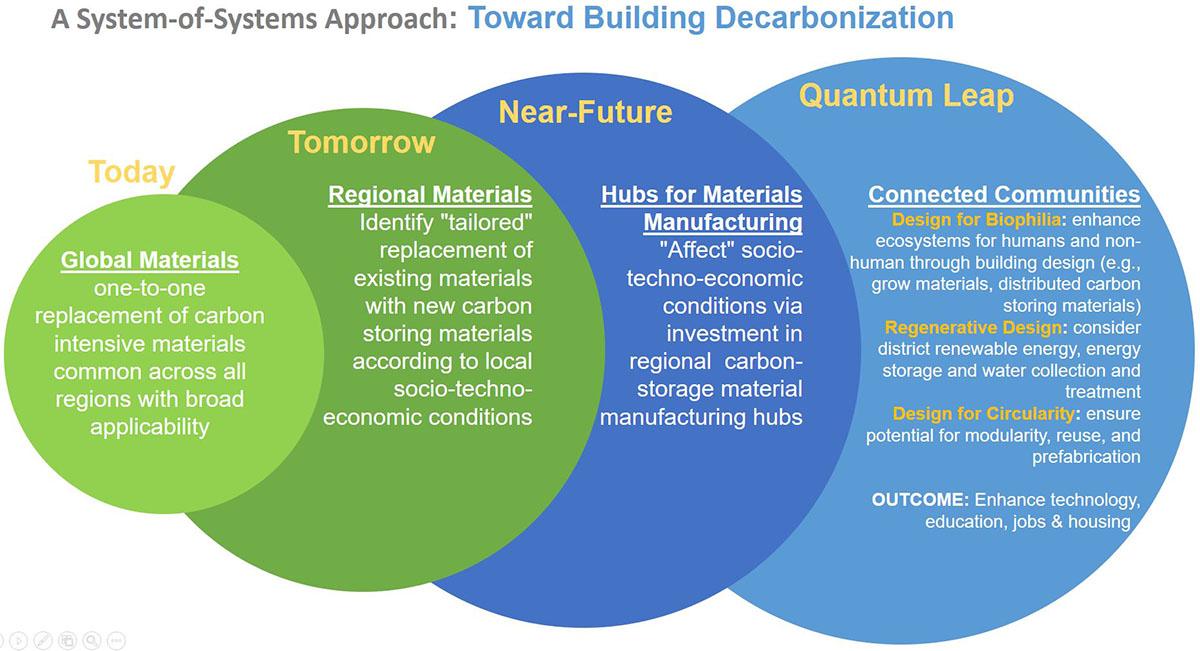

1.5 System-of-systems approach

The CLF’s mission to inspire and spur collective action to solve the embodied carbon challenge comprises an important piece of the climate change puzzle that can be expanded through system-of-systems (SoS) thinking. When we consider the broader impacts of systems at multiple scales (e.g., community-wide, regionally, globally), an SoS mindset envisions our built and natural systems as composed of interwoven threads creating a fabric crucial to healthy systems for our planet, communities, and building industries. When we pull on various threads, an SoS approach reveals how low-carbon and carbon-storing materials, manufacturing, building, human, and natural environments are connected. The intersections of these threads offer spark points for innovative strategies.

For this study, the team envisioned the future technology campus as a “Hub” that will catalyze new regional product manufacturing industries to contribute to the construction of a connected community of buildings both within and beyond the boundaries of day-to-day technology operations.

Taking an incremental and sequential approach, the team first sought to map materials for immediate one-to-one replacement of carbon-intensive materials common across all regions and applicable to core technology center facilities globally. Next, the team identified opportunities to incorporate appropriate regional materials for replacement of existing materials with new carbon-storing materials according to local socio-techno-economic conditions of a selected region of North America. Then, recognizing that a technology campus project can affect socio-techno-economic conditions via investment in regional low-carbon and carbon-storage material manufacturing hubs, we sought to identify potential impacts on mature, emergent, and non-existent markets. For example, partnering with local agricultural businesses to include “agricultural residue” products in the manufacturing of materials like hempcrete could incorporate regionally appropriate fibers found in tobacco, sunflower, or rice plants into building materials.

Finally, the team sought to enhance opportunities for connecting low-carbon and carbon-storing materials research, design, manufacturing, and construction practices to local communities for housing, education, and employment. Opportunities for connected communities include (see Figure 3):

- Design for biophilia. Enhance sustainable communities for humans and non-humans through design (e.g., grow low-carbon materials on site, foster distribution of carbon-storing materials).

- Regenerative design. Use of district renewable energy, energy storage, water collection, and renewable materials (e.g., use energy and water to support adjacent communities).

- Design for circularity. Ensure potential for modularity and reuse through prefabrication of components and building assemblies and reuse.

- Beyond the boundaries of the campus. Enhance technology, education, jobs, and housing in support of the local economy and workforce training.

[1] See Section 4 for further information on these opportunities

The team sought to enhance opportunities for connecting low-carbon and carbon-storing materials research, design, manufacturing, and construction practices to local communities for housing, education, and employment.

Figure 3. A system-of-systems approach: Toward Building Decarbonization (credit: Julie Kriegh).

The WBLCA was conducted by WSP Engineering in 2020.

2 Whole Building Life Cycle Assessment

2.1 WBLCA overview

A whole building life cycle assessment (WBLCA) of an existing light industrial building was conducted in order to establish a benchmark for a prototypical building. This analysis was performed in Tally, an LCA tool that is integrated with Revit (a building information modeling (BIM) software). This single-story building is an approximately 287,602 square-foot facility. It is a steel-framed, pre-engineered metal building (PEMB) with a concrete foundation. Operational energy was not assessed.

The building scope of the WBLCA included:

- Structural elements, such as beams, columns, and slabs

- Enclosure elements, such as walls, roofs, finishes, waterproofing

- Interior walls

The building scope excluded:

- Elements or material systems that made up less than 5% of the total mass of the building

- Mechanical, electrical, and plumbing (MEP) systems

- Miscellaneous items such as data storage equipment; landscape elements; fire detection and alarm systems; parking lots; site improvements; finishes on the interior floors and ceilings; railings; and non-structural partitions.

The following life cycle stages were assessed:

- A1: Raw material supply

- A2: Transport (from raw material supply site to manufacturing site)

- A3: Manufacturing

- A4: Transport (from manufacturing site to building site)

- B2: Maintenance

- B3: Repair

- B4: Replacement

- B5: Refurbishment

- C2: Transport (from building site to waste disposal site)

- C3: Waste processing

- C4: Disposal

- D: Benefits and loads beyond the system boundary (e.g., recycling, energy recovery)

The building scope of the WBLCA included structural elements, such as beams, columns, and slabs; enclosure elements, such as walls, roofs, finishes, waterproofing; and interior walls.

2.2 WBLCA results

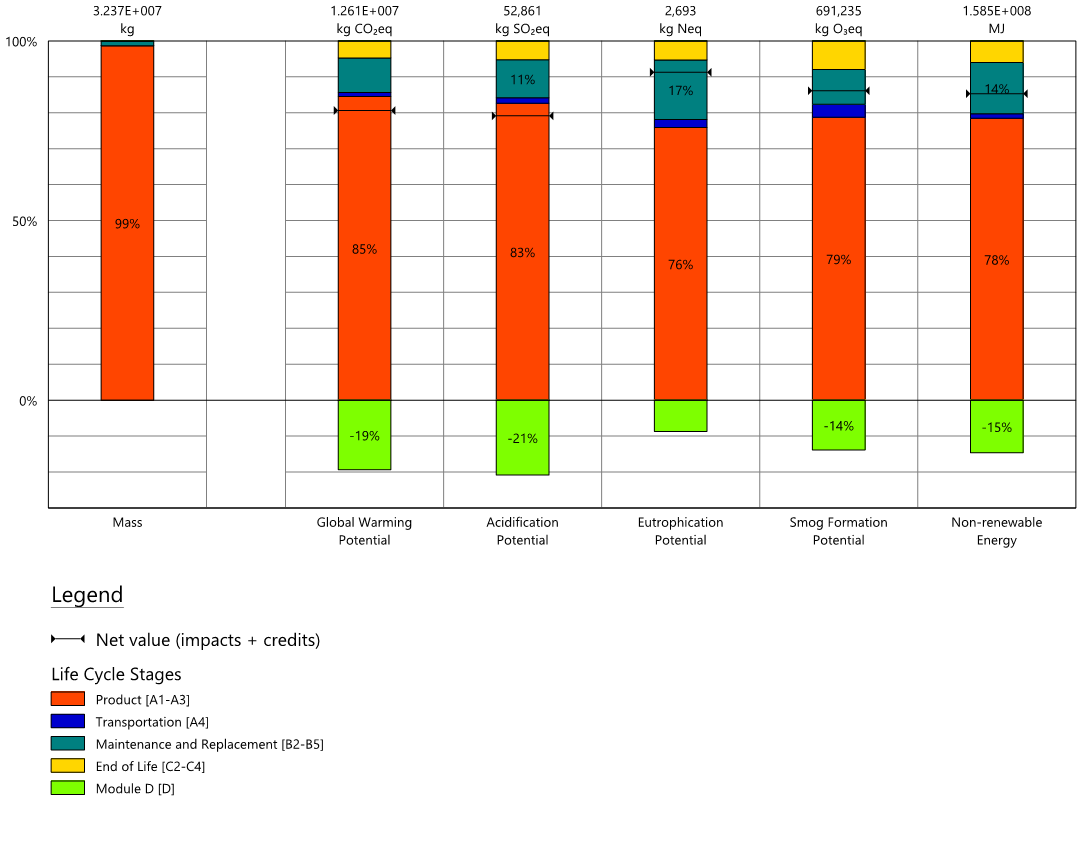

The embodied carbon footprint of the prototypical building was calculated to be approximately 380 kgCO2e/m2. Table 1 presents a summary of the overall WBLCA results, covering all life cycle stages. Ideas on how to reduce the embodied carbon of specific building components are discussed in the next subsection.

Table 1. Summary of WBLCA results, reflecting life cycle stages A1-A4, B2-B5, C2-C4, and D (credit: WSP Engineering).

| Measure | Units | Result | Result normalized by gross floor area (units/m2) |

| Global warming potential | kgCO2eq | 10,165,381 | 380 |

| Acidification potential | kgSO2eq | 41,835 | 1.56 |

| Eutrophication potential | kgNeq | 2,457 | 0.09 |

| Ozone depletion potential | kg CFC-11eq | 0.26 | 9.59E-06 |

| Smog formation potential | kgO3eq | 595,370 | 22 |

| Primary energy demand | MJ | 146,950,819 | 5497 |

| Non-renewable energy demand | MJ | 135,212,453 | 5058 |

| Renewable energy demand | MJ | 11,698,460 | 438 |

| Mass total of materials | kg | 32,368,779 | 1211 |

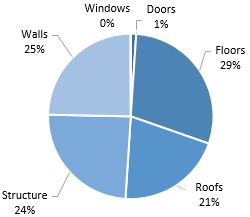

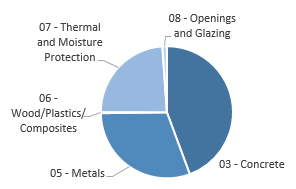

Figure 4 shows the contributions from different building categories to the overall global warming potential (GWP) or embodied carbon impact of the building. Figure 5 shows the contributions to total GWP by material division. This figure shows that concrete, metals, and insulation (a.k.a. “Thermal and Moisture Protection”) make the greatest contributions to GWP.

Figure 4. Contributions to total GWP by category (credit: WSP Engineering).

Figure 5. Contributions to total GWP by material division (credit: WSP Engineering).

Figure 6 shows the contributions to overall environmental impacts by life cycle stage. This figure shows how the Product stage made the biggest contribution to the embodied impacts of the building.

Figure 6. Contributions to overall environmental impacts by life cycle stage, results from Tally (credit: WSP Engineering).

2.3 Bay slice study

A bay slice refers to one structural bay with half a structural bay on each side is open on each side. A bay covers approximately 5000 square feet of area. A bay slice was used to model the following alternative designs:

- Steel baseline case

- Steel proposed case

- Glulam proposed case

The key materials in the different bay slice models are shown in Table 2.

Table 2. Key materials in different bay slice models (credit: WSP Engineering).

| Steel – Baseline Case | Steel – Proposed Case | Glulam – Proposed Case |

| · Total Concrete Structure | · Total Concrete Structure | · Total Concrete Structure |

| · Total Steel Structure | · Total Steel Structure | · Total Steel Structure |

| · Total Glulam Structure | ||

| · 6″ Gravel Base | · 6″ Gravel Base | · 6″ Gravel Base |

| · Base-of-Wall Cladding | · MetlSpan C42 Wall | · Benson Wood Wall Panel |

| · MetlSpan C42 Wall | · MetlSpan CFR42 Roof | · Benson Wood Roof Panel |

| · MetlSpan CFR42 Roof | · IsoSpan | · IsoSpan |

| · Louver + Bird Screen | · Louver + Bird Screen | · Louver + Bird Screen |

| · XPS Rigid Insulation, excluding XPS at Base-of-Wall Cladding | · XPS Rigid Insulation – Footing Only | · XPS Rigid Insulation – Footing Only |

The results from the bay slice study are shown in Table 3. The assessment was conducted by WSP Engineering in Tally and assumed a service life of 60 years for the building. Biogenic carbon was included in the results for modules A1-A4, B, C, and D (the treatment of biogenic carbon was taken on a 100-year timeline in alignment with GWP 100 standard). In this case it is assumed that the life of the building is less than 100 years and the full disposal and degradation cycle will occur. Results are reported with and without the benefits and loads of biogenic carbon. Results show that using glulam in place of steel can reduce the embodied carbon by at least 60% compared to the baseline case (see Table 3).

Table 3. Summary results from bay slice study reflecting life cycle stages A1-A4, B2-B5, C2-C4, and D. (credit: WSP Engineering).

| Case | GWP (kgCO2eq) | Absolute GWP reduction from steel baseline case (kgCO2eq) | % GWP reduction |

| Steel Baseline | 484,404.80 | – | – |

| Steel Proposed with biogenic carbon | 433,691.92 | 50,712.88 | 10.47% |

| Steel Proposed without biogenic carbon | 434,243.11 | 50,161.69 | 10.36% |

| Glulam Proposed with biogenic carbon | 142,284.93 | 342,119.87 | 70.63% |

| Glulam Proposed without biogenic carbon | 167,670.02 | 266,021.90 | 65.39% |

2.4 Discussion

Building components that had the potential to be replaced with low-carbon and carbon-storing alternatives were identified and organized in three implementation time horizons: 1-to-1 replacements (implementable within one year), near-future replacements (2-3 years), and innovative strategies enabling a carbon-positive future (3-5 years). Potential reductions in embodied carbon increase dramatically at each time horizon, with a net neutral or even carbon-storing balance achievable within a five-year time frame:

- 1-to-1 replacements → 20% reductions achievable immediately

- Near-future replacements → 60% reductions achievable within 2-3 years

- Carbon-positive approach → 100% reductions achievable within 3-5 years

The recommended carbon-storing materials and strategies fall into five distinct categories, addressing the current design’s embodied carbon hotspots:

- Concrete foundations (footings and slabs). Minimization of concrete elements and improvements to concrete specifications are the single most important factors to achieve emission reductions in the immediate term. Sizable reductions are possible in the near term as developments in concrete formulation progress, with opportunities for leadership in adoption. Carbon-sequestering aggregate and biogenic cementitious materials offer the potential to reduce the carbon footprint of concrete to zero within five years.

- Structural framing. The embodied carbon of the current steel frame of the building design can be reduced by conscientious steel procurement (e.g., electric arc furnace steel or direct reuse). A switch to a glulam timber frame offers significant emission reductions and, with appropriate sourcing of the timber, could lend substantial carbon storage to the building.

- Building enclosure. The current metal-insulated panels (MIPs) with foam insulated cores can be improved only minimally by procurement decisions. However, a switch to wood-framed panels with cellulose insulation with appropriate detailing for fire protection achieves major reductions and carries the potential for a high amount of carbon storage. Panels currently available on the market with cellulose insulation offer suitable replacements for current MIPs in the near term. Wood-framed panels could be optimized within five years to be entirely carbon-storing, made from certified wood or bamboo and natural fiber insulation that is regionally-sourced, based on the panels currently being produced in limited quantities.

- Louvers and bird screens. Aluminum fabrications are currently used in the design, with limited opportunities for emission reduction via responsible sourcing. Bio-composite materials using agricultural fibers and bio-resins offer potential replacements within 3-5 years, a shift that would enable this portion of the building to achieve zero emissions or net carbon storage.

- Purpose-grown fibers, earth, and waste. Throughout the building, many opportunities can be found to use building materials based on regionally appropriate natural fibers, soils, and waste streams, including sheet goods, flooring, cladding, millwork, interior panels, and finishes. All of these choices would contribute to increased carbon storage capacity.

WBLCA assessment and Bay Slice study were conducted by WSP Engineering in Tally and reported in a June 10, 2020 memo.

Potential reductions in embodied carbon increase dramatically at each time horizon, with a net neutral or even carbon-storing balance achievable within a five-year time frame.

3 Findings and Recommendations

3.1 1-to-1 replacements

Materials research demonstrated that simple material substitution made to general specifications and low-carbon material procurement strategies can yield a 20% reduction in embodied carbon compared to the baseline WBLCA (see Table 3).

Key recommendations for short-term (immediate) implementation are as follows:

- Concrete foundations (footings and slabs). Minimize the use of concrete. Edit master specifications to specify design compressive strength of concrete @ 56 (or 90) days; remove limits of 30% maximum SCM content and specify 40% minimum SCM content where appropriate; specify limits in cement content (verifiable with concrete mix design submittal and batch ticket) and/or embodied carbon (verifiable with EPDs) per compressive strength category per region; and encourage use of Type IL cements, which are now widely available.

- Foundations (perimeter wall). Despite a relatively small impact on overall emissions, a move to using biogenic insulated concrete forms (e.g., IsoSpan, Nexcem IsoSpan) would enable a scenario in which use of more innovative concrete mixes requiring longer curing times would not slow the construction schedule because the formwork is permanent.

- Structural systems. Source all steel from electric arc furnace (EAF) facilities and/or encourage direct reuse where appropriate.

- Wall and roof panels. In the current design, wall and roof panels are constructed of metal insulated panels (MIPs) filled with extruded polystyrene (XPS) or expanded polystyrene (EPS) foam insulation cores. Analysis showed that no significant reduction in emissions could be demonstrated by substituting mineral wool for the current foam-based insulation in the MIPs. However, manufacturers may be open to supplying cellulose insulation in lieu of extruded polystyrene (XPS) or expanded polystyrene (EPS) foam panels as an alternate.

Simple material substitution made to general specifications and low-carbon material procurement strategies can yield a 20% reduction in embodied carbon compared to the baseline WBLCA.

3.2 Near-future replacement

Even with the 20% reductions achievable today through short-term changes, building systems will remain responsible for significant outputs of carbon. Material substitutions and low-carbon strategies implementable in the near-future (2-3 years) provide a roadmap to transform technology campuses from carbon-emitting building platforms to carbon sinks. For example, the near-future WBLCA does not incorporate a CLT floor/foundation (with appropriate detailing) or bio-based louvers, but these elements would further and significantly reduce the carbon footprint of the building (see Table 3).

Key recommendations for near-future (2-3-year implementation) are as follows:

- Concrete foundations (footings and slabs). Edit master specifications to mandate Type IL and/or LC3 cements; explore potential partnerships with alternative cement/concrete and carbon-storing aggregate and filler manufacturers; work with concrete suppliers to prompt their transition to natural, more sustainable SCMs; engage a CLT manufacturer/design firm for conceptual design and analysis of CLT foundations in place of concrete.

- Structural systems. Redesign the steel structural system to accommodate a glue-laminated (glulam) engineered wood structural system with appropriate fireproofing considerations.

- Wall and roof panels. Engage a manufacturer of wood-frame/cellulose wall and roof panels (e.g., prefabricated panels) to establish appropriate design parameters and finishing options; work with panel manufacturer to source sustainably harvested wood products for panels; work with design team and panel manufacturer to ensure panels are easily dismountable at the end of the building’s lifespan; encourage panel manufacturer to produce an EPD for the panels.

- Louvers and bird screens. Connect with a biofiber and bioresin fabricator to design an appropriate louver and bird screen system to replace the current aluminum version; encourage the fabricator to produce an EPD for the product to quantify emission reductions and storage potential.

Material substitutions and low-carbon strategies implementable in the near-future (2-3 years) provide a roadmap to transform technology campuses from carbon-emitting building platforms to carbon sinks.

3.3 Carbon-positive future

These strategies can reduce emissions by at least 60% (see Table 2), and potentially more, depending on the accounting for biogenic carbon.

Key strategies for a carbon-positive future (3-5 year implementation) are as follows:

- Fiber-based materials. In general, agricultural biofibers are regionally available and highly abundant. Biological fibers such as hemp, straw, and other agricultural residues, as well as seaweed, could be used as building blocks for strong, durable building materials. Proof-of-concept and small-scale technologies already exist to transform biofibers into building materials. These technologies can be scaled and replicated in other regions around the world.

- Earth-based materials. Similar to biofibers, earth-based materials abound, as does the knowledge and practical know-how to build strong, durable, insulative, fire-resistant earth structures. Opportunities exist for (1) introducing compressed earth block technologies in regions where they do not yet exist and (2) combining earth blocks with biofiber reinforcements, panels, or insulation materials to create high-performance carbon-storing envelope assemblies.

- Purpose-grown materials. The power and potential of rapid photosynthesis and the unique abilities of photosynthetic organisms can be harnessed in the manufacturing and “growth” of carbon-storing materials. Algae, for example, can be used to create biofuels and biochar as well as a multitude of other functional bioproducts, such as inks, foods, carbon-storing mineral fillers for concrete, and other load-bearing carbon-storing building materials and finishes. Algae (and photosynthesis more broadly) could thus serve as a nexus for a carbon-storing community.

- Waste stream materials. Measures can be taken to prevent waste-stream biogenic materials from returning carbon to the atmosphere. Municipal recycling systems and regional industrial by-products can often furnish raw materials for a wide variety of building materials. Such materials are in production in many places today and could be encouraged near technology centers. Partnerships in research and development with companies exploring new recycled materials can be fostered.

Algae can be used to create biofuels and biochar as well as a multitude of other functional bioproducts, such as inks, foods, carbon-storing mineral fillers for concrete, and other load-bearing carbon-storing building materials and finishes.

4 Discussion and Future Directions

Paradigm shift toward a carbon-positive future

A transition to a carbon-positive future can be facilitated by a paradigm shift in perspectives of technology campuses as the center of carbon-storing communities. A pivot of this type will necessitate design changes that go beyond emission reductions and promote carbon-storing materials and strategies that contribute even further to meeting carbon-neutral goals by 2030. As increasing numbers of companies pivot to support global strategies exemplified by existing and emergent regional industries worldwide, a paradigm shift from carbon emission reductions to carbon-storage strategies will follow, meeting both the values and goals stated below:

- Lead by example. Set new and disruptive business-as-usual standards for an impact that has global reach with regard to carbon storage in design and construction practices, both on technology center campuses and in local communities and industries.

- Influence materials production. Support manufacturing practices to foster industry adoption with a focus on globally strategic plans to promote the production of new region-specific biogenic materials (e.g., fiber and purposefully-grown materials).

- Take a holistic approach. Foster carbon-storing communities that includes mutual co-benefits for the local people, environment, and economy. This model essentially focuses on the importance of photosynthetic (carbon) drawdown and fostering community-based co-benefits for the new biogenic materials industries. Existing examples include: energy-flexible buildings tied to a smart grid, district heating and cooling relationships with a local community, transit-oriented and development linking transportation to housing, economic opportunity zones pairing agriculture residue products with materials manufacturing, and education and workforce training partnerships with local universities. This report suggests that a technology center could comprise the hub for carbon-storing communities.

- Be future-ready. Be a leader in the future carbon economy and a pioneer in the eco-ag-tech industry. Design for prefabrication, modularity, circularity, and reuse will enable future flexibility.

The pivot to a carbon-positive future will necessitate design changes that go beyond emission reductions and promote carbon-storing materials and strategies that contribute even further to meeting carbon-neutral goals by 2030.

5 Limitations and Future Applications

Limitations and future applications

Limitations. This study did not thoroughly investigate potential changes to: building codes, material assemblies with respect to moisture, humidity and temperature, architectural design, structural engineering, cost estimating, and construction schedules or specifications.

Future applications. We anticipate that there are several notable next steps in the development of carbon-storing materials including:

- Code revisions

- Identify code and standards barriers to adoption of new materials

- Engage in standards and code development process to support revisions

- Support testing and certification as needed to address concerns such as fire resistance/water

- Pilot materials

- Engage an architectural, engineering, and construction teams to evaluate materials with respect to cost, schedule, life safety, building codes, fire, humidity, and other performance specifications, and product availability

- Investigate new and innovative biogenic materials in early stages of development

- Prototype buildings

- Build small but impactful prototype, not necessarily industrial campus

- Consider demonstration projects for affordable housing and community center structures

- Address opportunities and barriers

- Promote EPDs for materials, LCAs, policies, tools, and methodologies

- Provide corporate incentives for new materials/manufacturing and education/careers

- Develop survey instruments addressing opportunities and barriers to market adoption including: environmental values, design, engineering, manufacturing, and construction practices

- Evaluate opportunities to transform the avoided and stored carbon into carbon assets that can be sold on emerging carbon marketplaces for buildings

- Advocate for environmental justice

- Advocate for environmental justice with respect to climate impacts, materials and manufacturing, access to economic opportunities through business development, education, and job training

- Endorse carbon-storing materials to promote healthy outcomes for people, prosperity and the planet

6 References

Cantor, D., and Manea, D. (2015). Innovative building materials using agricultural waste. Science Direct, Energy Procedia, Elsevier Lt,126 (201709) pp. 456-462. www.elsevier.com/locate/procedia.

Churkina, Galina, Alan Organschi, Christopher PO Reyer, Andrew Ruff, Kira Vinke, Zhu Liu, Barbara K. Reck, T. E. Graedel, and Hans Joachim Schellnhuber (2020). Buildings as a global carbon sink. Nature Sustainability, pp. 1-8.

IPCC, 2018: Global warming of 1.5°C. An IPCC Special Report on the impacts of global warming of 1.5°C above pre-industrial levels and related global greenhouse gas emission pathways, in the context of strengthening the global response to the threat of climate change, sustainable development, and efforts to eradicate poverty [V. Masson-Delmotte, P. Zhai, H. O. Pörtner, D. Roberts, J. Skea, P.R. Shukla, A. Pirani, W. Moufouma-Okia, C. Péan, R. Pidcock, S. Connors, J. B. R. Matthews, Y. Chen, X. Zhou, M. I. Gomis, E. Lonnoy, T. Maycock, M. Tignor, T. Waterfield (eds.)]. https://www.ipcc.ch/sr15/download/

Frank, S., Beach, R., Havlik, P., Herrero, M., Mosnier, A., Hasegawa, T., Creason, J., Ragnauth, S., and Obersteiner, M. (2018). Structural change as a key component for agricultural non-CO2 mitigation efforts. Nature Communications, pp. 1-8. DOI:10.1038/s41467-018-03489-1: www.nature.com/nature.

Halbert, G., Rock, M., Steininger, K., Lupisek, A., Birgisdottir, H., Desing, H., Chandrakumar, C., Pittau, F., Passer, A., Rovers, R., Slavkovic, K., Hollberg, A., Hoxha, E., Juisselme, T., Nault, E., Allacker, K., and Lutzkendorf, T. (2020). Carbon budgets for buildings: harmonizing temporal, spatial and sectoral dimensions. Buildings and Cities, 1(1), pp. 429-452. DOI: https://doi.org/10.5334/bc.47.

Kriegh, J., Magwood, C., Srubar, W. (2020). Carbon-Storing Data Centers: Final FY20 Report. University of Washington, Carbon Leadership Forum, Industry Report.

Liuzzi, S., Sanarica, S., and Stefanizzi, P. (2017) Use of agro-wastes in building materials in the Mediterranean area: a review. Science Direct, Energy Procedia, Elsevier Lt,126 (201709) pp. 242-249. www.elsevier.com/locate/procedia.

Maraveas, C., (2020). Production of Sustainable Construction Materials Using Agro-Wastes. Materials, 2020, 13, 262. pp. 1-29. www.mdpi.com/journal/materials.

7 Carbon-Storing Materials Index

| Carbon Leadership Forum | Carbon-Storing Materials Index Kriegh, J., Magwood, C., Srubar, W. 2021 |

|||

| Time / Years | Strategy Prototype | Strategy Replacement Material | Product / Company Links |

| Foundations/Slab | |||

| 1-1 | Foundations- Concrete Structural Piers and Slab Floor | Low-Carbon Concrete (High SCM & 56- and 90-Day Design Compressive Strength) | https://www.marincounty.org/-/media/files/departments/cd/planning/sustai… |

| 2-3 | Foundations- Concrete Structural Piers and Slab Floor | New concrete technologies (see also below biological aggregates and SCMs) | https://www.solidiatech.com https://www.blueplanet-ltd.com |

| 2-3 | Foundations- Concrete Structural Piers and Slab Floor | Cross Laminated Timber (CLT) foundation | CLT Handbook. https://info.thinkwood.com/clt-handbook |

| 1-1 | Foundations – Perimeter Wall | IsoSpan and Nexcem | https://www.isospan.eu/en/ https://nexcembuild.com/ |

| Biological Aggregates & Biological SCMs | |||

| 3-5 | Carbon-positive Future Materials | Purpose-Grown Materials | |

| 3-5 | Carbon-positive Future Materials | Carbon8 aggregates Blue Planet | https://c8s.co.uk https://www.blueplanet-ltd.com/ |

| 3-5 | Carbon-positive Future Materials | Photosynthetic microorganisms (algae) | |

| 3-5 | Carbon-positive Future Materials | Zeobond (Alternative Cement Concrete) | https://zeobond.com |

| 3-5 | Carbon-positive Future Materials | Foam glass/Glavel | https://www.glavel.com/ |

| 3-5 | Carbon-positive Future Materials | Palm kernel ash/palm kernel shell | https://www.researchgate.net/publication/279919872_The_Use_of_Palm_Kerne… |

| 3-5 | Carbon-positive Future Materials | Biomason | https://www.biomason.com |

| Structure | |||

| 1-1 | Structural | Framing Steel- Electric Arc Furnace Steelmaking | |

| 1-2 | Structural | Mass timber (glulam, etc) | https://www.apawood.org/manufacturer-directory |

| 1-1 | Wall and Roof Panels MIP | Cross laminated timber (CLT) | https://www.apawood.org/manufacturer-directory https://www.nationalobserver.com/2020/03/30/opinion/canadas-forests-beco… |

| Thermal and Moisture | |||

| 2-3 | Wall and Roof Panels MIP | Bensonwood prefabricated wall and roof panels | https://bensonwood.com/building-systems/panelized-enclosures/ |

| 1-1 | Wall and Roof Insulation | Cellulose insulation | https://www.cellulose.org/index.php https://www.cmsgreen.com/insulation/ecocell-batts |

| 3-5 | Carbon-positive Future Materials | Cellulose foam | https://news.wsu.edu/2019/05/09/researchers-develop-viable-environmental… |

| 3-5 | Carbon-positive Future Materials | Fiber-based Materials and Systems | |

| 3-5 | Carbon-positive Future Materials | Ecococon straw/timber | https://ecococon.eu/ca/ |

| 3-5 | Carbon-positive Future Materials | Bamcore wall system | https://bamcore.com/ |

| 3-5 | Carbon-positive Future Materials | Modcell | https://modcell.com/ |

| 3-5 | Carbon-positive Future Materials | Stramit straw panels | https://www.strawtec.com/ https://www.ekopanely.com/ https://isobioproject.com/partners/stramit-international-strawboard-ltd/ |

| 3-5 | Carbon-positive Future Materials | Hempcrete (panels) | https://americanlimetechnology.com/wp-content/uploads/2012/02/Hembuild_He… |

| 3-5 | Carbon-positive Future Materials | Just Biofiber blocks | https://justbiofiber.ca/ |

| 3-5 | Carbon-positive Future Materials | Agriboard | https://www.agriboard.com/ |

| 3-5 | Carbon-positive Future Materials | Fiber-based board and panel systems | |

| 3-5 | Carbon-positive Future Materials | Vesta Eco straw boards | https://www.vestaeco.com/Products,3.html |

| 3-5 | Carbon-positive Future Materials | Kenaf/hemp/corn/bagasse/sorghum board | https://www.americansorghum.com/sorghums-eco-friendy-building-material/ |

| 3-5 | Carbon-positive Future Materials | Seaweed | Danish manufacturer https://convert.as/ |

| 3-5 | Carbon-positive Future Materials | Hempwood | Hempwood recent startup in Kentucky https://hempwood.com/ |

| 3-5 | Carbon-positive Future Materials | Wheat straw MDF | https://web.archive.org/web/20220609044824/https://www.novofibre.com/ |

| 3-5 | Carbon-positive Future Materials | Corn cob particle board | https://www.jmaterenvironsci.com/Document/vol7/vol7_N4/138-JMES-1811-201… |

| 3-5 | Carbon-positive Future Materials | Torzo boards | https://torzosurfaces.com/ |

| 3-5 | Carbon-positive Future Materials | Fiber-based Materials and Systems | |

| 3-5 | Carbon-positive Future Materials | Rice hull panels | https://hdgbuildingmaterials.com/products/resysta/ |

| 3-5 | Carbon-positive Future Materials | Resysta | https://hdgbuildingmaterials.com/products/resysta/ |

| 3-5 | Carbon-positive Future Materials | Hemp corrugated siding | https://margentfarm.com/ |

| 3-5 | Carbon-positive Future Materials | Rice straw MDF | https://calplant1.com/product/ |

| 1-5 | Carbon-positive Future Materials | Cement bonded wood wool | https://www.armstrongceilings.com/commercial/en-us/articles/tectum-part-… |

| 1-5 | Carbon-positive Future Materials | Mycofoam | https://ecovativedesign.com/ |

| 1-5 | Carbon-positive Future Materials | TTS panels and blocks | https://ttsfpl.com/products/ |

| 1-5 | Carbon-positive Future Materials | Wood fiber board | https://golab.us/ |

| 1-5 | Carbon-positive Future Materials | Hemp panels | https://hempearth.ca/products/hempearth-hemp-board/ |

| 1-5 | Carbon-positive Future Materials | Rice hull panels | https://hdgbuildingmaterials.com/products/resysta/ |

| 1-5 | Carbon-positive Future Materials | Cork | https://www.thermacork.com/external-walls/ |

| 1-5 | Carbon-positive Future Materials | Biochar | https://www.biochar-journal.org/en/ct/3 |

| 1-5 | Carbon-positive Future Materials | Rewall | https://www.continuusmaterials.com/ |

| 3-5 | Carbon-positive Future Materials | Earth- based Materials and Systems | |

| 3-5 | Carbon-positive Future Materials | Watershed blocks | https://watershedmaterials.com/ |

| 3-5 | Carbon-positive Future Materials | Clay panels | https://www.acoustix.be/produits/acoustix-pan-terre/ https://ecobuildingboards.weebly.com/uploads/5/0/7/3/5073481/ebb-overvie… |

| 3-5 | Carbon-positive Future Materials | Earthen floors | Claylin in Oregon https://claylin.com/ |

| 3-5 | Carbon-positive Future Materials | In situ rammed earth | Numerous contractors throughout North America https://nareba.org/ |

| 3-5 | Carbon-positive Future Materials | Compressed earth blocks | Numerous suppliers and installers throughout USA https://dwellearth.com/ |

| 3-5 | Carbon-positive Future Materials | PISE sprayed earth | Numerous suppliers and installers throughout USA https://semmesco.com/specialties/thick-wall-construction-methods/#rammed-earth |

| 3-5 | Carbon-positive Future Materials | Clay-based paints | Numerous suppliers and installers worldwide https://www.bioshieldpaint.com/index.php?main_page=index&cPath=144&zenid… |

| Other Insulation Technologies | |||

| 1 | Carbon-positive Future Materials | Cement bonded wood wool | https://www.armstrongceilings.com/commercial/en-us/articles/tectum-part-… |

| 3-5 | Carbon-positive Future Materials | Rice hulls | |

| 3-5 | Carbon-positive Future Materials | Textile waste insulation | https://www.researchgate.net/publication/235953688_Textile_waste_as_an_a… |

| 3-5 | Carbon-positive Future Materials | IsoStrau | https://www.iso-stroh.net/ |

| 3-5 | Carbon-positive Future Materials | Wool | https://havelockwool.com/ |

| 3-5 | Carbon-positive Future Materials | Bagasse | https://www.sciencedirect.com/science/article/abs/pii/S092134491300058X |

| 3-5 | Carbon-positive Future Materials | Solomit straw panels | https://solomit.com.au/acoustic-strawboard-ceilings/ |

| Other Construction Technologies | |||

| 3-5 | Carbon-positive Future Materials | Lichen | |

| 3-5 | Carbon-positive Future Materials | Green roof | https://liveroof.com |

| SoS Strategies | |||

| 1-5 yr | Carbon-positive Future | Systems of Systems approach to Grow a Greenr Campus/connected community | |

| 1-5 yr | Carbon-positive Future | Prefabricated modular systems/Prefabricated modular components | |

| 1-5 yr | Carbon-positive Future | Circularity / design for deconstruction and reuse | |