Version: December 17, 2020

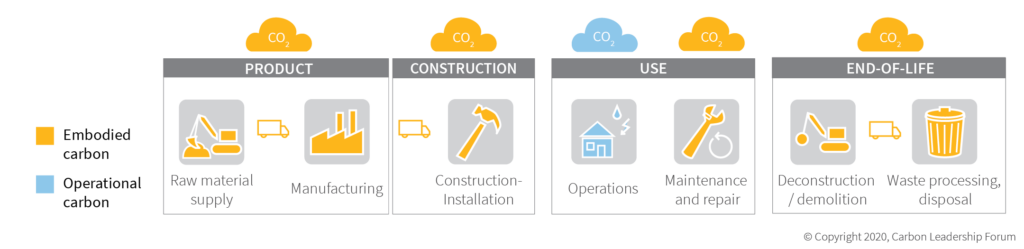

Figure 1. Embodied carbon (yellow) and operational carbon (blue) across the key life cycle stages of a building.

Understanding Embodied Carbon

Measuring embodied carbon

In the building industry, embodied carbon refers to the greenhouse gas emissions arising from the manufacturing, transportation, installation, maintenance, and disposal of building materials. In contrast, operational carbon refers to the greenhouse gas emissions due to building energy consumption.

In order to quantify greenhouse gas emissions and their potential effects on climate change, scientists use a method called life cycle assessment (LCA) to track the emissions produced over the full life cycle of a product or process. These emissions are converted into metrics that reflect their potential effects on the environment. One of these metrics is global warming potential (GWP), which is quantified in kilograms of CO2 equivalent (kg CO2e). This quantity is also commonly referred to as a carbon footprint.

Embodied carbon is an urgent issue

According to the Paris Agreement, in order to avoid an irreversible and catastrophic climate change trajectory, average global temperatures must not rise more than 2°C. Since (1) emissions accumulate in the atmosphere and (2) there is limited time remaining before the arrival of this tipping point, emissions released now are more critical than emissions released later.

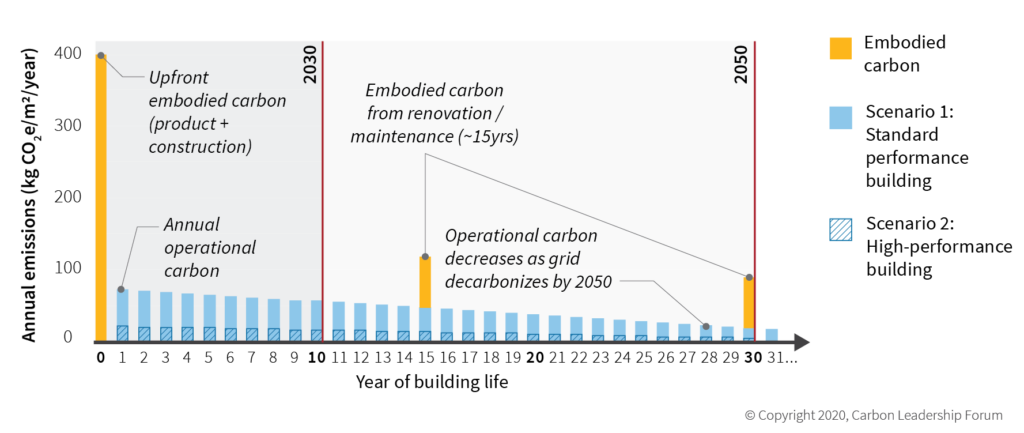

The majority of a building’s total embodied carbon is released upfront in the product stage at the beginning of a building’s life (see Figure 2). Unlike with operational carbon, there is no chance to decrease embodied carbon with updates in efficiency after the building is constructed. There is an urgent need to address embodied carbon now to meet short-term and long-term climate targets. For more information about this concept, see The Time Value of Carbon.

Figure 2. Relative impact of embodied and operational carbon of a new building from 2020-2050. Data sources: Embodied Carbon Benchmark Study and Commercial Buildings Energy Consumption Survey (CBECS), assuming a medium-sized commercial office building. Assumes gradual grid decarbonization to zero by 2050.

The Global Footprint of Embodied Carbon

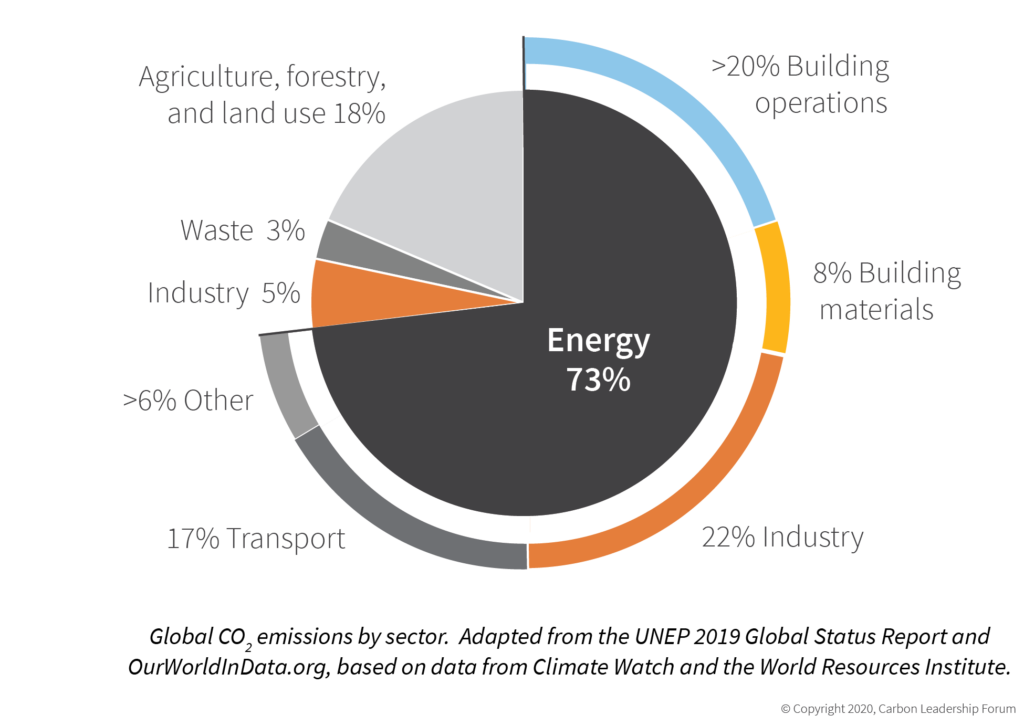

Approximately 30% of all global carbon emissions are attributed to the building sector, with at least 8% resulting from the manufacturing of construction materials (see Figure 3). An additional percentage of global emissions can be attributed to embodied carbon from the industry and waste sectors.

Unless we take action soon to reduce emissions arising from construction materials manufacturing, these emissions will continue to increase due to:

- Increased global demand for construction materials to accommodate population growth, particularly in cities

- Replacement of aging infrastructure, which in the US is an investment of approximately $4.6 trillion, according to ASCE’s 2017 Report Card for America’s Infrastructure

- Decreased relative proportion of emissions from building operations as building energy efficiencies continue to improve

Figure 3. Global CO2 emissions by sector. Adapted from the UNEP 2019 Global Status Report and OurWorldInData.org based on data from Climate Watch, the World Resources Institute. Building material emissions also occur in the Industry and Energy > Industry sectors.

Policy Strategies for Addressing Industrial Emissions

Industrial emissions require new strategies

Two of the largest sources of industrial sector emissions are (1) the production of cement and (2) the production of iron and steel (IEA). Reducing cement and steel emissions requires a unique approach because the production of both of these materials includes:

- Chemical reactions that directly emit carbon dioxide; and

- Energy-intensive processes that require very high heat and (often) on-site combustion of fossil fuels.

A successful clean manufacturing transition therefore requires strategies that go beyond energy reductions to consider a range of carbon emissions reduction and removal strategies.

While reducing embodied carbon in buildings starts with action in the industrial sector, the construction industry has a key role by creating a market demand for lower-carbon products. Public and private policy can both send a signal to manufacturers that it is time to invest in short- and long-term solutions.

Addressing the carbon loophole

Procurement policies are a key lever for incorporating a broader suite of reduction strategies and avoiding the carbon loophole. The carbon loophole is a policy gap that allows one region to reduce emissions on paper by outsourcing their manufacturing emissions to another region. Approximately 25% of global emissions are embodied in traded goods that pass through this loophole (KGM & Associates and Global Efficiency Intelligence).

This loophole exists because emissions are typically attributed to their source country or location. This method leaves the source location to track and regulate a product’s emissions therefore results in an unfair economic advantage for higher carbon products produced in countries with less advanced environmental policies.

To encourage emissions reductions rather than emissions outsourcing, policies should focus on measuring and reducing embodied carbon in the design and construction of buildings.