GSA Announces 150+ Projects with $2 billion in Funding for Clean Construction Materials

Primary Authors: Meghan Lewis (Carbon Leadership Forum), Walter Tersch (GSA), Katie Poss (Building Transparency)

In August 2022, the historic Inflation Reduction Act (IRA) Section 60503 appropriated $2.15 billion of funding to the U.S. General Services Administration (GSA) to procure substantially lower embodied carbon (LEC) construction materials for use in federal building and paving projects. This funding builds on GSA’s P100 Facilities Standards for concrete and asphalt (sections 4.8.5 and 4.8.6) and 20% whole-building embodied carbon reduction (P100 section 1.9.2.9), along with information gained through the interagency Federal Buy Clean Initiative. GSA’s new low-carbon material requirements – together with the Department of Transportation’s upcoming Low-Carbon Transportation Materials Grants Program – advances progress towards the federal sustainability goal to reach net-zero emissions procurement by 2050.

Winning GSA project bids without low embodied carbon materials will be tough

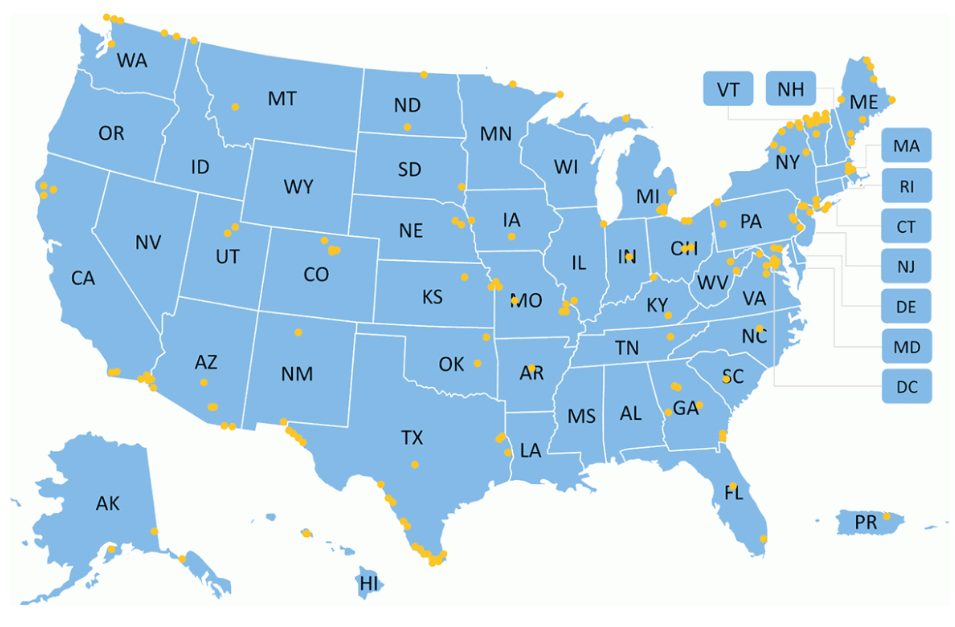

In December 2023, GSA published a map of over 150 projects around the country that will now be eligible for using IRA funding for low embodied carbon (LEC) materials. GSA also put together a handy list of materials for each project Hier.

For these 150 planned IRA LEC projects, securing low-carbon products is critical for contractors to receive awards. GSA’s initial IRA solicitations have employed best value selection procedures that include environmental attributes — including a Sustainability factor that evaluates whether proposals include low carbon materials in as many relevant product subcategories as possible — in addition to price.

If contractors cannot provide concrete, steel, glass, and asphalt materials that are at least better (lower-carbon) than average, their proposals may be considered non-responsive and ineligible for award.

What must design and/or construction contractors include in a GSA proposal for IRA LEC projects?

To be eligible for the $2.15 billion of IRA funding, eligible construction materials (asphalt, concrete, glass, and steel) must: (1) meet GSA’s IRA Low Embodied Carbon (LEC) GWP limits for each material that were established pursuant to an EPA Determination on what qualifies as “substantially lower” levels of embodied carbon; (2) provide a product-specific Type III environmental product declaration (EPD) at the time of bid that is based on the product category rule specified in GSA’s requirements; and (3) provide the ENERGY STAR Energy Performance Score and location of the flat/float glass plant, integrated steel mill (if applicable), or cement plant that provided material for a concrete mix.

An EPD is required in 100% of IRA LEC cases; there is no waiver process. Depending on how the GWP stacks up, it is possible that material manufacturers may need to make production changes (e.g. lower-carbon concrete mix designs or different fuel sources) to meet the GWP limits, especially at the “Top 20%” limit. Contractors are therefore well-advised to identify materials that will both (a) meet the job’s specific performance needs AND (b) have an EPD that meets GSA’s requirements, to be ahead of the curve in avoiding schedule, budget, or eligibility impacts. During proposal preparation, prime contractors may seek to identify LEC suppliers by consulting EPD maps and databases. If designers or builders want to help ensure their preferred material suppliers (e.g. concrete, asphalt, steel, or glass companies) show up as potentially qualifying for GSA IRA projects, they can encourage the suppliers to get an EPD and upload it to relevant databases or directories.

While GSA cannot directly pay for a business to get an EPD, it generally awards construction contracts on a firm-fixed-price basis. Such pricing allocates responsibility for cost recovery to the business judgment of the prime contractor. Prime contractors commonly include direct and overhead costs in their overall pricing, such as:

- Supplier/ subcontractor costs, potentially including costs of creating facility-specific Type III EPDs, if none exist yet.

- If necessary, suppliers/ subcontractors revising product attributes to meet GWP limits. For example, to lower concrete’s carbon footprint, it may be necessary to revise mix designs, perform testing and evaluation, or use different supplementary cementitious materials, admixtures, or cements.

- Acquiring and transporting low carbon materials.

Until EPA starts issuing EPD assistance grants to up to 40 selected applicants later in 2024, manufacturers will need to pay for EPDs upfront to be eligible for GSA projects – both IRA projects, and – for concrete and asphalt – all GSA projects that use at least 10 cubic yards of a mix. Additionally, IRA funds may only be used on materials that, at minimum, meet “better than average” GWP limits.

NOW is the time for manufacturers to get an EPD to compete on IRA projects

In some regions, localized materials such as concrete and asphalt might have limited EPD availability. Because GSA’s P100 requires an EPD for all its projects (including non-IRA projects) that use at least 10 cubic yards of a concrete or asphalt mix, getting an EPD now can help differentiate firms from their competitors, especially where EPDs are relatively scarce. Another benefit to firms that get EPDs for low-carbon materials is that the Federal Highway Administration’s $2 billion IRA-funded Low-Carbon Transportation Materials Grants Program makes funding available to state and local DOTs, but only for materials that have EPDs, and substantially lower levels of embodied greenhouse gasses.

In some cases where firms have background data available (e.g. one full year of material and energy information), it may be possible for EPDs to be generated relatively quickly to meet project bid or construction deadlines. Timing matters for products like asphalt and concrete where mix designs may vary by project. For example, in Summer 2022, an asphalt company in Colorado was able to develop and provide its first EPD in five weeks to meet GSA’s P100 asphalt requirements, without any cost or schedule impact.

Although the government does not endorse specific products or services, CLF notes that EPD generation tools such as Klima Erde, Theta EPD, and the National Asphalt Pavement Association’s Emerald Eco-Label are designed to speed up the EPD development process, up and make it as simple and cost-effective as possible for manufacturers. For example, staff at WAP Sustainability (who owns the ThetaEPD tool) stated that concrete EPDs can be generated in just 6-8 weeks for $3,000 per plant and a one time verification fee of $1,000. There is a discount for members of the National Ready-Mix Concrete Association (NRMCA). NRMCA also maintains a page of EPD resources to help ready-mix suppliers get ready to create EPDs.

This month GSA announced the award of a LEC window replacement project at the Charles W. Whittaker U.S. Courthouse in Kansas City, MO.

GSA’s 6-Month Buy Clean Pilot

Late last year GSA wrapped up a six-month Buy Clean pilot focused on 11 federal buildings, U.S. courthouses, and land ports of entry around the country in Arizona, Colorado, Michigan, Missouri, New York, North Dakota, Texas, and Washington D.C. GSA used this pilot to gather market research on the availability of LEC construction materials. The pilot also helped raise awareness and build market capacity for providing compliant materials as GSA (and other agencies) prepare for the next phase of Buy Clean implementation.

During the pilot, over 5,000 additional EPDs were published for asphalt, concrete, glass, and steel, with flat glass EPDs nearly doubling and asphalt EPDs nearly tripling.

GSA found that American-made low embodied carbon materials are available, but geographic constraints on concrete and asphalt made procurement of those materials difficult along the northern and southern borders where fewer businesses are located. Mobile plants may be a solution for remote sites.

GSA’s first IRA-funded award procured American-made glass that met GSA’s 40% GWP limit at a price that was competitive with pricing for conventional glass — while delivering the same performance characteristics, and without any schedule impact. GSA continues to seek high-performance glass that meets the top 20% GWP limit, and has reason to believe that more EPDs and products will be available soon from U.S. glass manufacturers that meet their performance requirements.

American-made steel is available within all three GWP limits (Top 20%, top 40%, and Better than Average) for projects across the U.S., as steel is already frequently shipped from a relatively small number of manufacturing locations.

The Carbon Leadership Forum is excited to see this clean construction material leadership from the Federal government and its industry partners, and looks forward to providing resources and expertise that can help you, your company, and its suppliers on the road ahead.

Offenlegung: GSA helped author this article to ensure it accurately describes Federal low-carbon material policies; this document was therefore produced in part at U.S. government expense. Beyond discussion of GSA programs, any expressions of fact or opinion are those of the Carbon Leadership Forum. GSA does not endorse any firms, products or services referenced in this article.