CIMA: Decarbonizing the Building Envelope

by Rachel Stern, Executive Director of the Cellulose Insulation Manufacturers Association

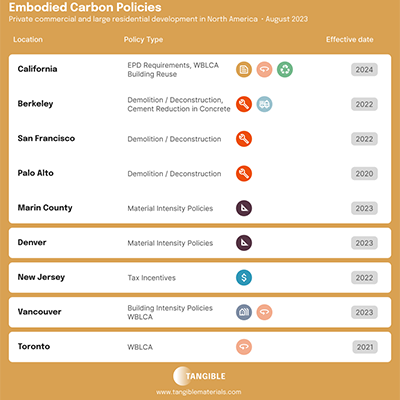

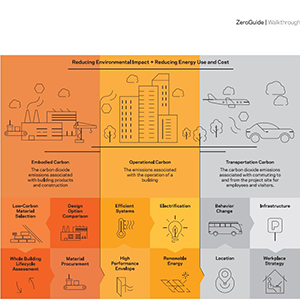

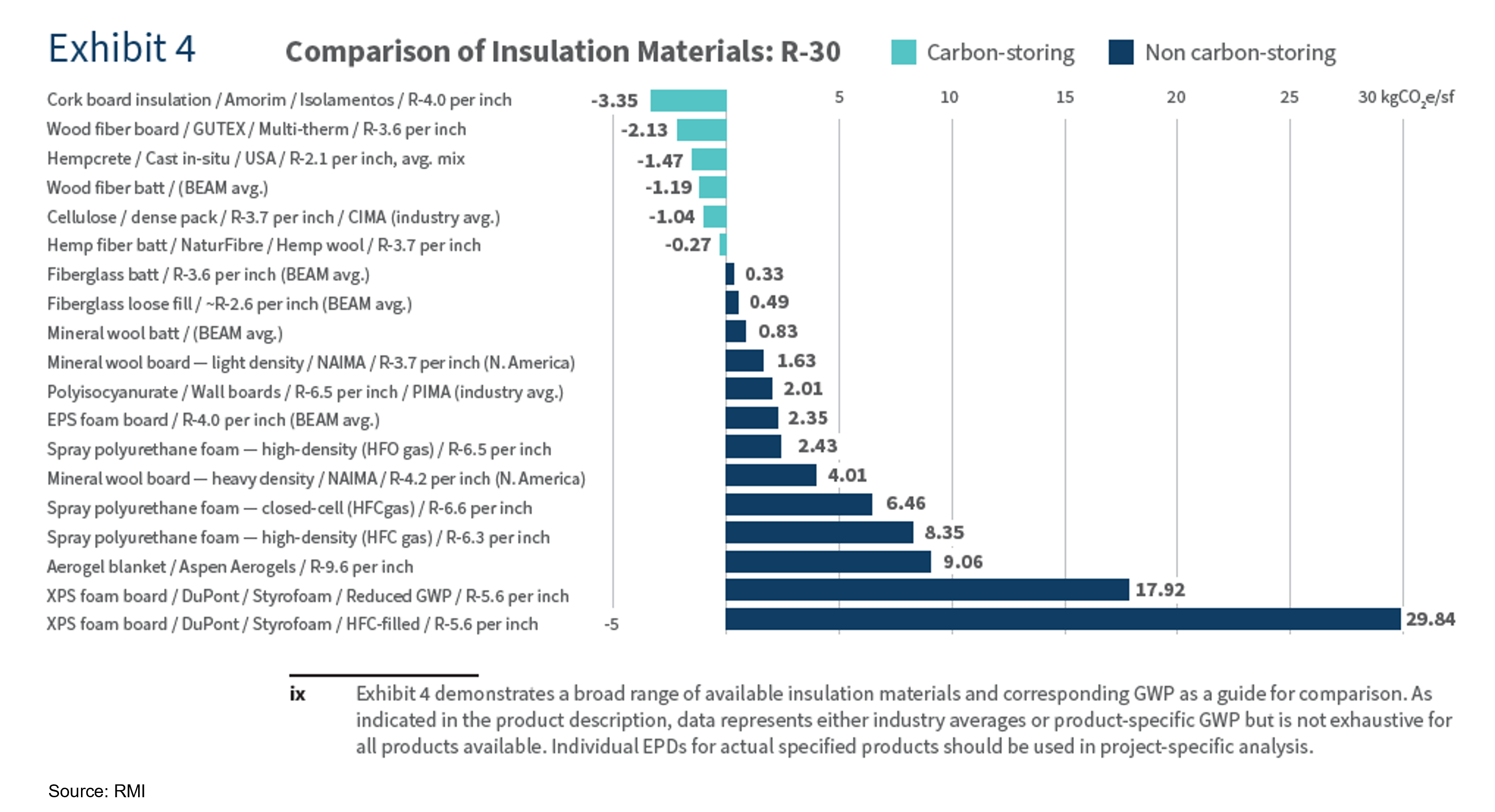

Several North American cities and states have passed laws and issued directives to reduce greenhouse gas emissions from all sectors, with many focused on reducing emissions from the construction and operation of buildings. As these goals become more prevalent, the building materials industry has an obligation – with plenty of incentives – to lower the embodied carbon of its products. Insulation should be a major component of this evaluation. Some insulation materials are manufactured with carbon-intensive processes, raw materials such as refined oil, involve long-haul transportation, and create high levels of VOCs and carbon emissions, while other insulation types are made from biogenic, plant-based materials that are not degraded after disposal. Rather, they capture carbon permanently (or sequester) it for the life of the building.

For over three decades, the Cellulose Insulation Manufacturers Association (CIMA) has been promoting naturally better insulation. Our members are composed of cellulose insulation manufacturers and suppliers across the United States and Canada. Initiatives like the Inflation Reduction Act (IRA) promote the use of insulation in existing homes and new construction. CIMA members and other insulation manufacturers advocate for weatherization as the first step to decarbonization. Adequate weatherization products like insulation and air sealing materials, which play a role in a building’s thermal envelope, reduce our reliance on electricity. Furthermore, fewer fossil fuels are consumed in well-insulated buildings.

Notiz: The chart for Exhibit 4 appears in a 2023 RMI report by Heather Clark, Chris Magwood, Victor Olgyay, and Eva Rosenbloom: Transforming Existing Buildings from Climate Liabilities to Climate Assets.

What is cellulose insulation and how does it work?

Cellulose insulation is the lowest embodied carbon building material commercially available. It is also the only form of (widely available) insulation that stores carbon in the product itself.[1] Loose-fill cellulose insulation is composed of up to 85% recycled newsprint and cardboard, higher than almost any other commonly used building material available on the market. Other elements in cellulose insulation include chemicals like boric acid, which is used as an insecticide and flame retardant, providing an effective one-hour fire rating. To highlight the carbon-storing potential of cellulose insulation compared with fiberglass:

- Insulating a typical 2,356 sq ft home with fiberglass insulation is expected to generate 2-3 tons of CO2 emissions associated with the production of fiberglass.

- Building the same structure with cellulose insulation would result in storing 5-6x the equivalent of tons of CO2 in the structure itself.

- The net swing in carbon emissions is estimated at 7-9 tons of CO2 per single-family home.[2]

In 2022, CIMA members sequestered over 292,000 tons of carbon.

Other benefits of cellulose insulation

While the environmental aspect of cellulose insulation is important, there are also many performance considerations that stand out.

- Thermal Protection: the R-values of cellulose and fiberglass batts are comparable, yet the density of cellulose and manner in which it is applied means greater access to those hard-to-reach spaces. As with all insulation, cracks and gaps should be air sealed first.

- Sound Benefits: cellulose insulation can absorb 80% or more of the sound it comes into contact with and may be used to achieve Sound Transmission Class (STC) ratings as high as 70 depending on the wall or partition assembly where the product is installed. This means less sound is transmitted through walls and ceilings.

- Fire Safety: all cellulose insulation is treated with fire retardants to meet federal, state/province, and local fire safety requirements. The addition of these chemicals will slow the spread of a fire, allowing you more time to escape any danger.

- Mold and Moisture Control: The hygroscopic nature of cellulose insulation allows it to manage and wick moisture from areas of greater to lesser concentrations, thus preventing damaging amounts of moisture from accumulating. This is a key distinction between cellulose and other types of insulation and an important benefit for homeowners when making insulation decisions.

- Retrofit Royalty: as noted on the EnergyStar website, it is still the case that 9 out of 10 homes are under-insulated.[3] The DOE has estimated that to retrofit even the half of US homes built before 1980, the national retrofit rate would need to increase 5x.[4] The DOE has also recognized that “States and local agencies decide what types of insulation materials work best in their respective [weatherization assistance] programs,” and “The most popular type of insulation materials used in the [weatherization assistance] program is cellulose.”[5]

Looking forward

With funding available for home energy programs in the IRA and the Canada Greener Homes Initiative, cellulose insulation continues to grow in popularity among builders, contractors, and homeowners. By using insulation with lower embodied energy, we are making significant strides in meeting carbon reduction targets. The support demonstrated through organizations like the Carbon Leadership Forum is beneficial to increasing awareness of our product. While the conversation around decarbonization is stronger than ever, seeing the dedication from this community ensures we are held accountable to the mission at stake.

References

[1] Builders for Climate Action, Low-Rise Buildings as a Climate Change Solution, Chris Magwood, 2019.

[2] Id. (With savings scaled to the average size of the US single family home of 2,357 sq ft per the latest US Census figures.)

[3] https://www.energystar.gov/campaign/seal_insulate/why_seal_and_insulate#

[4] US DOE DPA Roundtable: Building Insulation Pre-Read and Agenda, September 20, 2022.

[5] https://nascsp.org/wp-content/uploads/2018/02/wpn2010-16-1.pdf

For over three decades, the Cellulose Insulation Manufacturers Association (CIMA) has been promoting naturally better insulation. Mitglieder include cellulose insulation manufacturers and suppliers across the United States and Canada.

Rachel Stern

Chris Magwood

Director of Research at Builders for Climate Action