by Kabira Ferrell, Vice-President for Communications for the Softwood Lumber Board

Supporting the development of tools, transparency, and data to support the sustainable use of a premier biogenic material

Supporting the development of tools, transparency, and data to support the sustainable use of a premier biogenic material

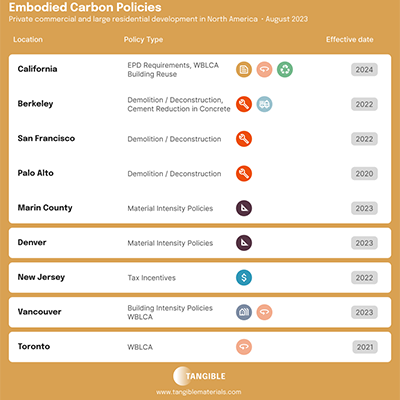

An estimated 80% of the embodied carbon attributable to building materials comes from structural products, making it vital to have accurate information when selecting structural building elements. Without decisive action, building materials used in new construction in cities across the globe will generate 100 gigatons of embodied carbon by 2050. The AEC community and the wood products sector have a shared goal—decarbonizing the built environment as expediently as we can.

Wood’s Carbon Footprint – A Quick 101

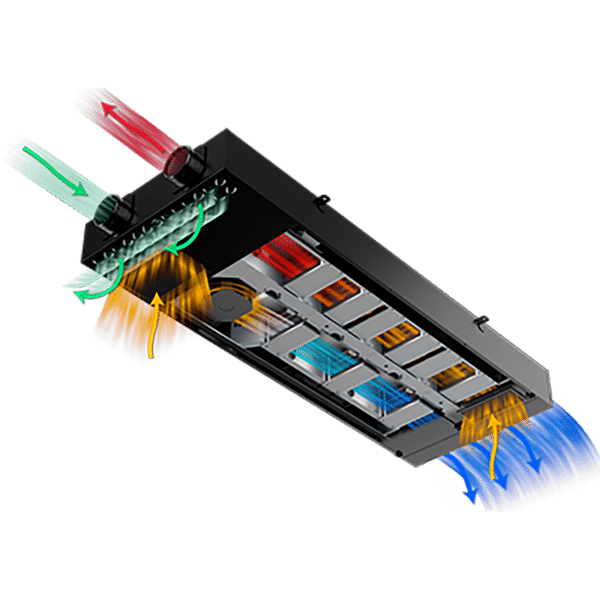

Manufacturing wood products is less energy intensive than the process for concrete or steel, which contributes to their low embodied carbon. Embedded carbon is the storage of carbon for long periods of time. Wood products are approximately 50% carbon by dry weight. The use of wood products in buildings provides an environmental benefit by storing carbon removed from the atmosphere.

Andy Quattlebaum Outdoor Education Center at Clemson University

Carbon Transparency Projects

Earlier this year, a team of subject matter experts, including the US Endowment for Forestry and Communities, American Wood Council, National Alliance of Forest Owners, and several forestry and wood products stakeholders, gathered to evaluate how existing and new research and tool development can meet stakeholder needs to better understand the carbon and environmental impact of growing and using wood products across the full value chain.

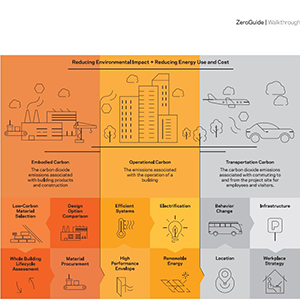

Three priority projects are underway to address questions from the AEC sector regarding wood’s carbon accounting to show how wood products and forests mitigate carbon emissions and the impacts of climate change.

A4 (Transportation) Data – We will compile information about wood product transportation between regions so that the carbon emissions from transportation (mill to a building site, the A4 stage) can be accurately modeled. The data will be made available for incorporation into LCA databases and whole building LCA (WBLCA) calculators, like BT’s Tally and as an add-on to EC3. This project is close to completion; it will be ready for roll-out in Q1 2022.

Wood Sourcing Tool – This tool will be designed to provide sustainability assurances, fiber supply and forest certification data at a regional level for US wood products in an easily accessed mobile-friendly website. Fiber procurement standards include: FSC Controlled Wood, Controlled Wood (fsc.org); SFI Fiber Sourcing Fiber Sourcing Standard – forests.org, and PEFC Chain of Custody standard Standards and Guides – PEFC – Programme for the Endorsement of Forest Certification. Forest Stewardship Council (FSC), Programme for the Endorsement of Forest Certification schemes (PEFC), and Sustainable Forestry Initiative (SFI) (https://forests.org/) are examples of forest management certification programs.

Woodshed Carbon Balance Tool – This tool will report forest carbon growth and drain by wood supply area. This information can be used to calculate a Scope 3 land carbon value for reporting to the Greenhouse Gas Protocol and for use with other carbon accounting frameworks currently under development. The first phase of the project will be to publish a peer reviewed article that outlines a methodology and corresponding regional results. In the second phase, the USDA Forest Service will develop and host the reporting tool.

Mass Timber Competition: Building to Net-Zero Carbon

In 2022, the SLB and USDA are jointly funding a $2M design competition to demonstrate mass timber’s application across select building types and ability to significantly reduce the carbon footprint of the built environment. Lessons learned from the competition will be shared with the broader design and construction community to help support future projects, including cost analyses, life cycle assessments, and other research results. Eligible building types include commercial, institutional, industrial, educational, mixed-use, and affordable multifamily housing developments.

Timber sourced for the project should demonstrate sustainable forest management that contributes to forest and watershed health. Several approaches are used to ensure sustainable supply of wood products, including federal, state, and local regulations, best management practices, third-party certifications, and an emerging ASTM standard. Preference will also be provided for projects that commit to using domestically harvested and manufactured mass timber.

The need to reduce carbon emissions is increasingly urgent. Now is the time for every emitting sector to evaluate their emissions, and consider how to lower their carbon footprint.

The Softwood Lumber Board (SLB) is an industry-funded commodity checkoff program established to promote the benefits and uses of softwood lumber products in outdoor, residential, and non-residential construction. SLB funds research and education as well as design and build technical consulting; codes and standards; and communications through its funded programs, WoodWorks, American Wood Council, and Think Wood.

Kabira Ferrell