An analysis of Environmental Product Declaration (EPD) definitions in Buy Clean and other North American procurement policies

A variety of existing and proposed legislation regulating public procurement at the federal, state, and city levels require the collection of environmental product declarations (EPDs) for reporting the greenhouse gas (GHG) emissions associated with building material production.

Authors

This research was conceived of and directed by the Carbon Leadership Forum. The research team from the Carbon Leadership Forum at the University of Washington College of Built Environments includes:

- Meghan Lewis, Senior Researcher, Carbon Leadership Forum

- Monica Huang, Researcher, Carbon Leadership Forum

- Brook Waldman, Researcher, Carbon Leadership Forum

- Stephanie Carlisle, Senior Researcher, Carbon Leadership Forum

- Kate Simonen, Executive Director, Carbon Leadership Forum

Author contributions: M.L. and K.S. led conceptualization; M.L., M.H., B.W., and S.C. conducted research and analysis; M.L., M.H., B.W., S.C., and K.S. performed review and editing; M.L. created the graphics; M.L. and M.H. wrote the paper.

Acknowledgments

The Carbon Leadership Forum’s policy initiatives and this work are funded by grants from foundations that support climate change mitigation research and clean energy policy. We would like to thank Anthony Hickling at the Carbon Leadership Forum for his role in funding acquisition and project administration.

We would like to thank Mikaela DeRousseau at Building Transparency for her contribution to the research included in this document, and to thank David Walsh from Sellen Construction and Jessica Koski from the Blue Green Alliance for their review of report drafts.

Additional ongoing organizational support for the Carbon Leadership Forum is funded by various philanthropic organizations including our sponsors, listed here:

Version: September 30, 2021

Citation

Lewis, M., Huang, M., Waldman, B., Carlisle, S., and Simonen, K. (2021). Environmental Product Declaration Requirements in Procurement Policies. Carbon Leadership Forum, University of Washington. Seattle, WA.

Cover image by Pixabay.

Competing interests statement

The Carbon Leadership Forum receives gifts from sponsors, including manufacturers and trade associations, which are listed here. Kate Simonen is on the board of directors of Building Transparency, a non-profit organization that supports the Embodied Carbon in Construction Calculator (EC3) tool, which includes a database of environmental product declarations.

Executive Summary

A growing number of local, state, and federal procurement policies require environmental product declarations (EPDs) for reporting the embodied carbon of eligible products. Embodied carbon refers to the greenhouse gas emissions arising from the manufacturing, installation, maintenance, and disposal of construction materials used in the construction of buildings, roads, and other infrastructure. Procurement policies such as Buy Clean aim to leverage the purchasing power of government agencies to incentivize transparency and a shift toward lower-carbon options in the broader construction materials market.

EPDs are appropriate for use in procurement policies because they already exist as agreed-upon resources for calculating and documenting the embodied carbon of products. There are limitations on the use of EPDs for comparison, and there is room to improve EPDs and product category rules (PCRs). Policies aiming to compare products across categories (such as between concrete and steel) should consider a building-scale approach and use whole building life cycle assessment (LCA).

EPDs and PCRs can be improved in the following ways to support the use of relevant and accurate data for comparison:

- Inclusion of supply chain–specific (i.e. primary) upstream data for processes with large impacts where secondary data is currently allowed.

- Inclusion of additional life cycle stages beyond A1-A3 into PCR requirements, where not already included.

- Inclusion of standardized default datasets in PCRs for upstream processes, including material manufacturing and transportation

- PCRs can be improved to better support the ability of manufacturers to comply with policies, such as facility-specific and supply chain–specific EPD guidance and guidance on inclusion of additional data in supplemental information.

Procurement policies are not currently harmonized in terms of the type of EPD that is required; existing and proposed legislation require facility-specific, product-specific, or supply chain–specific EPDs. Facility-specific and supply chain–specific EPD requirements were introduced by policymakers interested in upstream data that has not yet been included in the minimum requirements established by the PCR for an eligible product. Policymakers have also included requirements for additional data that can be reported in the supplemental information section of an EPD, such as the wood fiber sourcing data requirements proposed in Buy Clean Buy Fair Washington.

Policymakers may consider one of the following strategies to encourage harmonization and allow for the addition of eligible materials over time:

- Request supply chain–specific EPDs with additional life cycle stages beyond A1-A3.

- Require product-specific EPDs and participate in PCR development to encourage the inclusion of upstream data and additional life cycle stages in PCRs.

Introduction

A variety of existing and proposed legislation regulating public procurement at the federal, state, and city levels require the collection of environmental product declarations (EPDs) for reporting the greenhouse gas (GHG) emissions associated with building material production, including resource extraction, transportation, and manufacturing. One of the most well-known versions of this type of procurement policy is Buy Clean California, which was introduced and passed into law by the State of California in October 2017. Buy Clean California and similar policies aim to reduce the embodied carbon associated with the construction of publicly owned facilities by leveraging the purchasing power of government agencies to incentivize transparency and encourage a shift toward lower-carbon options in the broader construction materials market.

This document provides an overview of current EPD requirements in existing and pro- posed policies and an analysis of the supply chain–specific EPD definition introduced by the Buy Clean Buy Fair Washington Act in 2021.

Environmental product declaration (EPD)

EPDs are third party–verified documents written in conformance with international standards that report the environmental impacts of a product, including its global warming potential, based on life cycle assessment models.

Material-Scale Embodied Carbon Policies

Buy Clean and other low-carbon procurement policies incorporate purchasing requirements that address the GHG emissions from construction materials. The material- and procurement-focused approach utilized by Buy Clean legislation is one of several complementary approaches for reducing embodied carbon with policy.

A building-scale approach focuses on the embodied carbon impact of a project as a whole, as well as the assemblies and systems that comprise a building. This approach addresses a broader scope of materials (rather than only focusing on the highest-impact materials) and can invite additional strategies for embodied carbon reduction, such as material and building reuse, system and material comparisons (such as mass timber, steel, or spray foam vs. batt insulation), and material efficiency. Because materials are compared across the product categories, the entire life cycle of a product must be included when using whole building life cycle assessment (LCA) to compare the impact of design choices on embodied carbon.

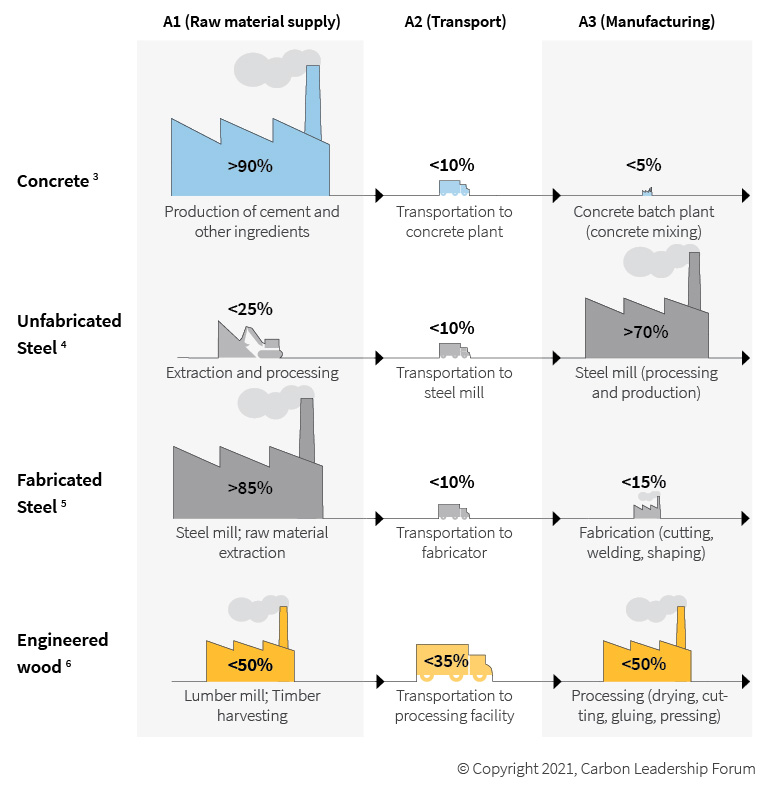

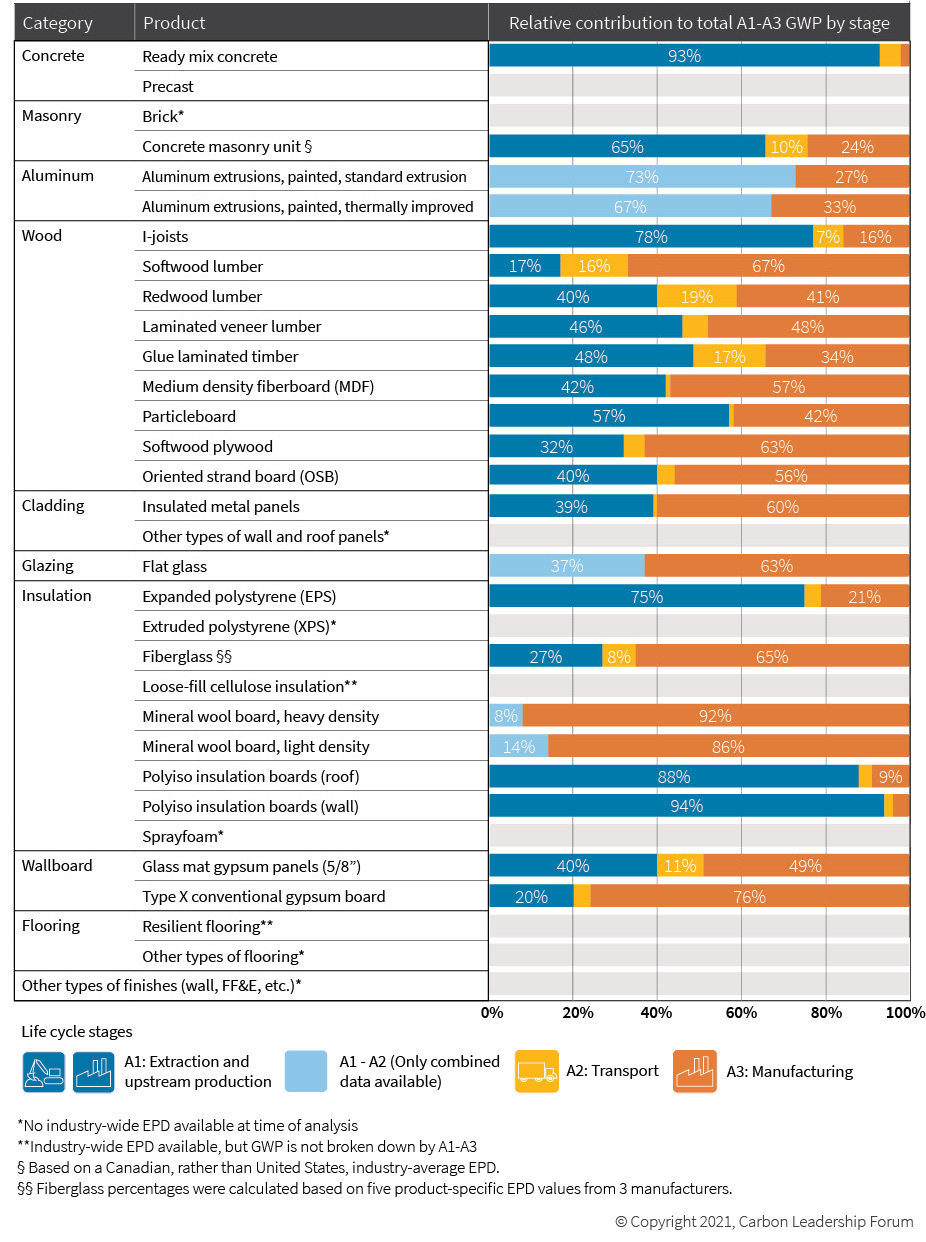

A material-scale approach focuses on the embodied carbon impact of individual construction materials and incentivizes transparency and availability of products made with lower-carbon manufacturing practices. A key component of this approach is requiring disclosure of high-quality embodied carbon data in the form of an EPD for materials specified by the policy. This approach is particularly relevant during the procurement phase of a project, when the product type and performance requirements have already been selected. Material-scale policies are well-suited for horizontal infrastructure, such as roads and bridges, in addition to buildings.

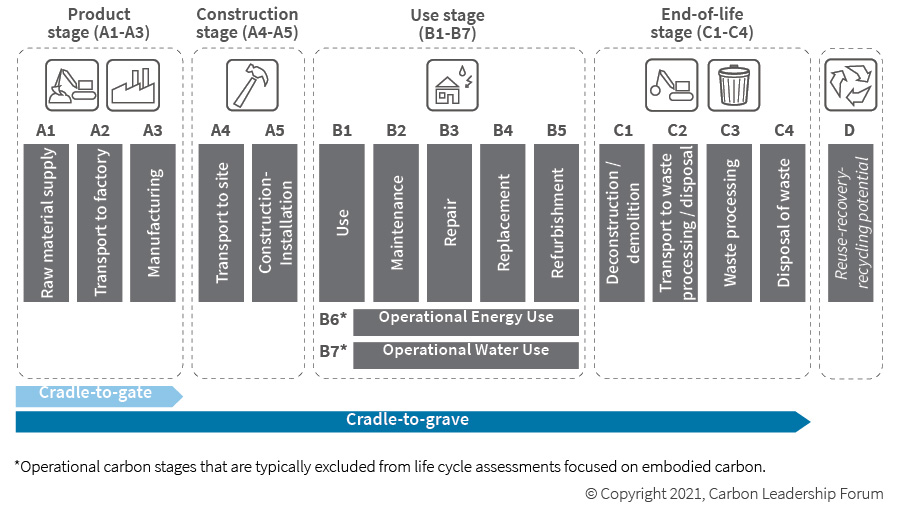

Currently, this approach is often limited to impacts in the early stages of a product’s life, from extraction to manufacturing, and to a handful of carbon-intensive materials, but this can change over time as standards improve and materials are added to policies.

Embodied carbon

Embodied carbon refers to the GHG emissions arising from the manufacturing, installation, maintenance, and disposal of construction materials used in the construction of buildings, roads, and other infrastructure. Embodied carbon is a life cycle impact called global warming potential calculated using LCA.

Life cycle assessment (LCA)

LCA is a systematic set of procedures for compiling and examining the inputs and outputs of materials and energy, and the associated environmental impacts directly attributable to a building, infrastructure, product or material throughout its lifecycle (ISO 14040: 2006).

EPD Requirements in Policies

The use of EPDs as standardized reporting tools for disclosing the global warming potential (GWP) of construction materials is increasingly prevalent in public procurement policy. EPDs are already used by consumers in the building industry to assess environmental impacts, enabling policymakers to build and improve upon the existing standards described in this section.

International Standards Organization (ISO) standards identify three types of environmental claims for products:

- Type I claims are third party–verified labels based on criteria set by a third party and are governed by ISO 14024.

- Type II claims are self-declarations made by manufacturers or retailers and are governed by ISO 14021. Type II claims are not third party–verified.

- Type III claims contain quantified product information based on life cycle impacts and are governed by ISO 14025. Type III claims must be third party–verified.

Of these three types of claims, Type III declarations are preferred for embodied carbon policy because they are third party–verified and contain the greatest amount of “quantified environmental information on the life cycle of a product,” which helps “enable comparisons between products fulfilling the same function” (ISO 14025: 2006).

The development of EPDs and product category rules (PCRs) are governed by a number of standards developed by the International Standards Organization (ISO), including:

- ISO 14025: Environmental labels and declarations — Type III environmental declarations — Principles and procedures

- ISO 14027: Environmental labels and declarations — Development of product category rules

- ISO 14040: Environmental management — Life cycle assessment — Principles and framework

- ISO 14044: Environmental management — Life cycle assessment — Requirements and guidelines

- ISO 21930: Sustainability in buildings and civil engineering works — Core rules for environmental product declarations of construction products and

Each material’s PCR dictates methodological decisions that are relevant and fine-tuned to the material supply chain of that product category (e.g., concrete, floor coverings, insulated metal panels, etc.). A PCR dictates which life cycle stages and scopes must be included in the LCA, which background data sources are acceptable or mandatory, and other modeling choices such as allocation method and impact assessment method.

EPDs vary in their level of product, supply chain, and regional specificity. The following categories of EPDs are used by purchasers to identify which level of specificity is required to comply with an EPD requirement:

Global warming potential (GWP)

The potential climate change impact of a product or process as measured by an LCA, reported in units (typically kilograms) of carbon dioxide equivalent (CO2e).

Product category rule (PCR)

A PCR is a set of specific rules, requirements, and guidelines for developing Type III environmental declarations for one or more product categories. Product category rules are reviewed and improved periodically over time.

- Industry-wide EPDs represent typical manufacturing impacts for a range of products for a group of manufacturers. Industry-wide EPDs provide the least specific data on a product’s embodied carbon footprint and cannot be used to compare products, but they are helpful in understanding the typical impact of a product.

- Product-specific EPDs represent the impacts for a specific product and manufacturer across multiple facilities.

- Supply chain–specific EPDs are defined in HB 1103 (Buy Clean Buy Fair Washington) in January 2021. A supply chain–specific EPD is a product-specific EPD that uses supply chain–specific data in the LCA to model the impacts of key processes upstream in a product’s supply chain.

- Facility-specific EPDs were introduced by the Buy Clean California Act in 2017. The California Department of General Services (DGS) defines a facility-specific EPD as a product-specific EPD in which the environmental impacts can be attributed to a single manufacturer and manufacturing facility.

Table 1 presents an overview of the EPD requirements in existing and proposed embodied carbon legislation.

PCRs provide guidelines for calculating industry-average EPDs and product-specific EPDs for each product type. For example, the PCR for concrete (NSF International, February 2019) defines product-specific EPDs as one “for a specific product or group of concrete mix designs categorized by performance developed by a manufacturer for a specific ready mix plant location” and an industry-average EPD as one “for a specific product or group of concrete mix designs categorized by performance for a specified region.”1 As of May 2021, PCRs do not provide facility-specific and supply chain–specific EPD guidance.

Supply chain–specific data

Supply chain–specific data refers to the use of primary, rather than secondary, data for upstream manufacturing or production processes.

An example of using supply chain–specific data is the use of a cement EPD from the cement plant sourced by a ready mix supplier rather than the use of generic data that represents industry average cement manufacturing in the United States.

1. NSF International. “PCR for Concrete.” February 2019. https://d2evkimvhatqav.cloudfront.net/documents/concrete_pcr_2019.pdf

Table 1. Overview of environmental product declaration (EPD) requirements in existing and proposed legislation focused on embodied carbon.

| Year introduced | Source | Bill | Type of EPD required |

| 2017 | California Legislature | Buy Clean California Act | Type III facility-specific EPD |

| 2019 | City of Portland | New requirements for concrete | Type III product-specific EPD |

| 2019 | Minnesota Legislature | HF 2204 | Type III facility-specific EPD |

| 2020 | New York State Senate | S542 (Original) | Type III product-specific EPD |

|

2021 |

California Legislature |

Type III supply chain–specific EPD Type III EPD that “makes use of supply chain-specific data for input materials whenever this data is available” |

|

| 2021 | Colorado State Assembly | HB 21-1303 | Type III EPD |

|

2021 |

Oregon State Legislature |

“Product-specific measurement of the life cycle environmental impact of a product, from the point of raw material extraction to the point of manufacture, that is certified by a third party and in accordance with international standards” | |

| 2021 | New Jersey Assembly | AB 5223 | Type III product-specific EPD |

| 2021 | Washington State Legislature | HB 1103 | Type III supply chain–specific EPD |

|

2021 |

House of Representatives, 117th Congress | H.R.1512 CLEAN Future Act – Subtitle C – Federal Buy Clean Program | Type III product-specific EPD “calculated for a specific facility” |

Many building sector professionals were first introduced to industry-wide and product-specific EPDs through the LEED v4 Materials and Resources credit Building product disclosure and optimization – environmental product declarations.2 Facility-specific and supply chain–specific EPDs were introduced by policymakers interested in upstream data that is not yet included in the minimum requirements established by the PCR for an eligible product.

EPDs are appropriate for use in procurement policies because they already exist as agreed-upon resources for calculating and documenting the embodied carbon of products. Additionally, EPDs are already used by consumers in the building industry to assess environmental impacts, so the infrastructure already exists to continue using EPDs and improving them. However, there are limitations on the use of EPDs for comparison. Policies aiming to compare products across categories should consider a building-scale approach and use whole building LCA tools rather than EPDs.

Limitations on use of EPDs

EPDs cannot be used to compare the environmental performance of two different materials (e.g., concrete and wood).

Comparisons between EPDs should only be made if their impacts were calculated using the same methodologies and life cycle modules and the products being compared are functionally equivalent.

Policies aiming to compare products across categories should use a building-scale approach relying on whole building LCA rather than EPDs.

2. United States Green Building Council, “Building product disclosure and optimization – environmental product declarations,” https://www.usgbc.org/credits/new-construction-core-and-shell-schools-new-construction-retail-new-construction-data-15?return=/credits/New%20Construction/v4.1

Conclusion

Procurement policies are not currently harmonized in terms of the type of EPD that is required; existing and proposed legislation require facility-specific, product-specific, or supply chain–specific EPDs. Facility-specific and supply chain–specific EPD requirements were introduced by policymakers interested in upstream data that has not yet been included in the minimum requirements established by the PCR for an eligible product. EPDs and PCRs can be improved in the following ways to support the use of relevant and accurate data for comparison:

- Inclusion of supply chain–specific (i.e. primary) upstream data for processes with large impacts where secondary data is currently allowed.

- Inclusion of additional life cycle stages beyond A1-A3 into PCR requirements, where not already included.

- Inclusion of standardized default datasets in PCRs for upstream processes, including material manufacturing and transportation impacts such as done by the 2019 concrete PCR.13

- PCRs can be improved to better support the ability of manufacturers to comply with policies, such as facility-specific and supply chain–specific EPD guidance and guidance on inclusion of additional data in supplemental information.

Table 4 summarizes the trade-offs between the use of different types of EPDs in procurement policies. To balance these trade-offs and encourage harmonization, policymakers may consider the following strategies:

-

- Request supply chain–specific EPDs with additional life cycle stages beyond A1-A3.

- Require product-specific EPDs and participate in PCR development to encourage the inclusion of upstream data and additional life cycle stages in PCRs.

13. NSF International. (2019). Product Category Rule for Environmental Product Declarations: PCR for Concrete.

Table 4. Summary of the pros and cons associated with different types of EPDs currently included in policies.

| Type of EPD | Pros (for use in policy) | Cons (for use in policy) |

|

Supply chain–specific Product-specific EPD that uses supply chain–specific (primary) data to model the impacts of key upstream processes (e.g. contribute >80% relative impact). |

• More accurately represents impacts of products with large upstream impacts • Appropriate for use across product types without identifying additional requirements, e.g. requires additional data only where significant (reducing burden on manufacturers) • Incentivizes sustainable sourcing and supply chain transparency |

• Less widely available • Guidance not yet available for manufacturers in PCRs |

|

Product-specific Represent the impacts for a specific product and manufacturer across multiple facilities. |

• More commonly available, reducing burden on manufacturers to create new EPDs • Appropriate for use across product types |

• Requires PCRs to be updated to include key data in order to meet policy goals • PCRs are slow to update and may not require key upstream supply chain data quickly enough to meet policy goals |

|

Facility-specific Product-specific EPD in which the environmental impacts can be attributed to a single manufacturer and manufacturing facility. |

• More accurately represents impacts of products sourced from a specific facility (e.g. grid mix, production methods, etc.) if impacts are concentrated in a single facility. |

• Less widely available • Incentivizes manufacturers to focus decarbonization efforts at only one facility • Appropriate for use only for products where the majority of impacts are at a single facility, rather than spread across a supply chain • Requires policymakers to set new EPD requirements as additional materials are required |