Enabling Contractors to Play a Leading Role in Reducing Embodied Carbon

Article by Brittany Harris, Qualis Flow Co-founder and CEO | Non-executive Director of the Environment Agency | Enterprise Fellow of the Royal Academy of Engineering

We can optimize our design to the nth degree on paper, specifying reused, recycled, and low-carbon materials, but what we specify in the digital world of design is not necessarily what is built in the physical world. However, it is in the physical world that we actually invoke the carbon emissions we aim to reduce.

Without verifying our impact throughout construction, we have little hope of truly tackling the colossal carbon footprint of our amazing industry. Additionally, without detailed data on the quality and quantity of materials in our assets, we won’t be able to maximize the reuse of materials in the future, further reducing our industries carbon footprint and unlocking the circular economy.

This is where Qflow comes in

Jade Cohen and I founded Qflow in 2018 on a mission to build a sustainable future, and to make that easy and profitable for the construction industry. Qflow is now the global leader in as-built construction material and waste data, unlocking insights from across supply-chains, cutting waste and preventing carbon emissions. Deployed on over $15BN of construction projects across the UK, US and Australia, we’ve generated a first of a kind construction industry waste insights report and demonstrated that prevention is better than reaction in construction.

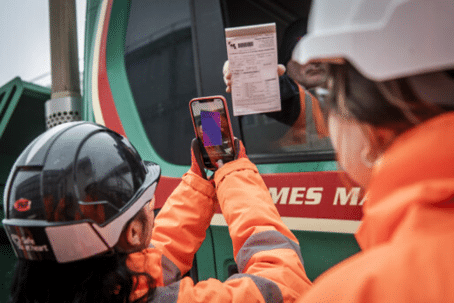

Despite the gradual move to more digital operations during construction, the records of what materials come onto site from our fragmented and under digitized supply chain is overwhelmingly still paper based (over 95% of deliveries are recorded in this way).

Qflow makes this paper digital, and ingests digital tickets too, creating a centralized and consistent record of materials received to site.

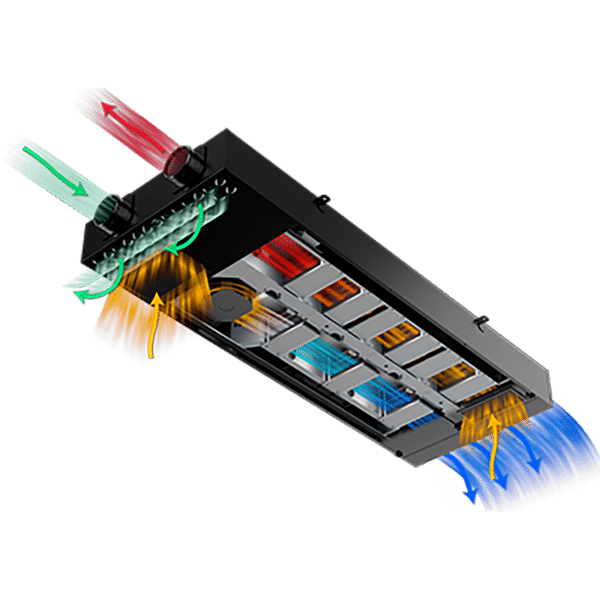

Isometric image showing the Qflow workflow: capture, digitize, analyze

Qflow captures all materials delivered to a project through a simple photograph of these paper receipts. Like Expensify for construction materials. No barcodes, no hardware…it’s as simple as taking a selfie! We then let our AI do the heavy lifting of digitising and auditing that data to identify:

- “Is this the right material for the project?”

- “Where has it come from?”

- “What does this mean for cost, quality and carbon?”

The bonus is that the data we capture to help drive more sustainable construction, is the same data that helps us build more efficiently and to a higher quality, which means less money wasted correcting mistakes…happy contractors, happy clients. With this we are saving construction teams hundreds of thousands of dollars and making the industry more sustainable and less wasteful.

We enable accountability and transparency across the construction supply-chain, meaning designers and architects can see their work take shape and manage variations as they arise, and that owners and developer have an accurate picture of their As-built assets and can manage the risk and opportunity that supply-chain changes present.

Photographing a delivery ticket for Qflow processing

Qflow in Action

- On Canary Wharf’s waterside community across 23 acres boasting 3,300 new homes, 2 million sq. ft of office space and 490,000 sq. ft of shops, restaurants, and community use Qflow saved project teams $240,000 and eliminating 36,5000kg of CO2e in the first year alone.

- Qflow tracked over 10,5000 material and waste movements, reducing reporting time by 85% saving over 208 hours, resulting in $140k per year saving for Skanska, Costain and Strabag on the High Speed Rail venture in the UK.

- Qflow enabled international contractor Bouygues to increase their supplier payments efficiency by 271%, enabling them to meet contractual commitment and win more work.

Most importantly, Qflow is easy to use and quick to deploy.

“Qflow makes the site process more efficient and less admin heavy, so it’s easy to get site teams’ buy-in.” — Glen Roberts – Operations Director, Wates Residential

Illustrating Qflow material insights applied to a tower job site

A brave new circular world

Today, Qflow is helping to reduce construction waste and transport emissions. But this is not what is going to move the needle on our industry’s colossal environmental footprint. To do this, we must transform our industry from linear and consumptive to circular and regenerative.

The data we capture today will form the foundations of a circular material market feeding the construction industry of the future. This data will enable architects and designers to identify materials about to become available for reuse, including their original manufacturer and standards/certifications (known as material passports). We hope that this will feed a whole new industry of online marketplaces, reclamation and remanufacturing companies, and insurers and certifiers. The potential of a new green economy is huge.

There are so many moving parts to delivering this utopia; this is a team effort. We are not working towards it alone. There are organizations around the world tackling different pieces of the puzzle. We are dedicated to the data piece and actively collaborating with our industry to promote more transparency across the entire supply chain.

So, what’s been our carbon impact so far?

To date, as a company, Qflow has emitted 117 tonnes CO2e, and helped prevent over 9,600 tonnes CO2e from being emitted. We publish our carbon impact every year. In this report, we quantify both the carbon we emit as a company and how we minimize this, and the carbon that we help our customers avoid emitting. Quantifying carbon avoided is a really difficult thing to do, and we are learning and tweaking our approach every year. We get this externally reviewed by mentors in the carbon space to help ensure we are robust in our calculations and assumptions. And with every evolution, we are as transparent as we can be about how we get to the final numbers and what we’ve learned. You can find this publicly on our website aquí.

If you want to get an accurate and transparent picture of your embodied carbon or want to find out more about how this data is used to support quality and cost control during construction, then feel free to reach out to the team via our website.

Jade Cohen and Brittany Harris, Qflow co-founders

Without verifying our impact throughout construction, we have little hope of truly tackling the colossal carbon footprint of our amazing industry. Additionally, without detailed data on the quality and quantity of materials in our assets, we won’t be able to maximize the reuse of materials in the future, further reducing our industries carbon footprint and unlocking the circular economy.